Armoured Cable Gland

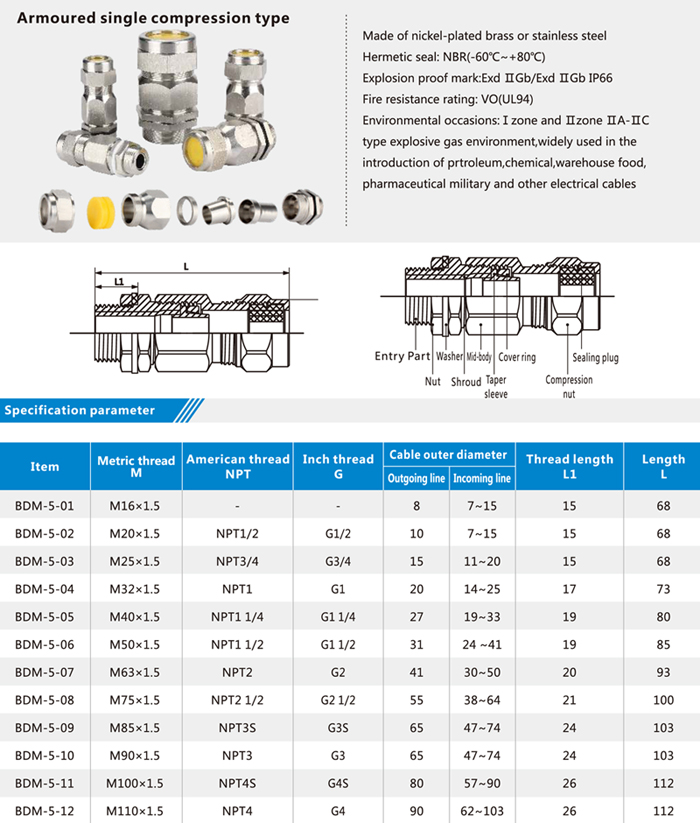

Armoured cable gland is a special type of terminating cable gland, they are designed for wire braid cables applied in a hazardous area with ATEX Certificates. Armoured cable diameter size is bigger than normal cables because of the armoured wires and outer sheath, so the size calculation in mm must consider this factor.

Armoured cable glands are normally made of a stainless steel material or brass material to provide strain relief for the armoured cables. This metal material could ensure the cable gland with anti-corrosion function, which could ensure it performs in good condition in explosion-proof requirement circumstances.

The armoured cable gland kits could ensure the waterproof function reaching IP66 grade, such as PV shrouds, lock nuts, and earth tag, which is very important for outdoor applications. The thread types are available for metric, NPT, PG etc., and the cable diameter size ranges from M20 to M110.

CEO Notes

Hey, Thank you for visiting our website. We could provide you with all of the armoured cable gland sizes by different raw material: nickel-plated brass and stainless steel. Our armoured cable gland could be made to be single compression and double compression types. We also could design the cable gland according to our customers' special requirements.

Questions You May Ask About Our Armoured Cable Gland

The armoured cable outer diameter size must be in the clamping range of the armoured cable gland.

Then peel off the outer protective shielding of the SWA cable, measure the length you need, and cut it to be suitable size.

Of course, it must be grounded. If the armoured cable is not grounded, eddy currents will be generated in the armored steel tape if the current through the cable is large enough. The steel tape will heat up, and the current-carrying capacity of the armoured cable will decrease.

Cut the SWA cable to a suitable length to fit the nozzle, the steel wire should stretch slightly to cover the armoured cable gland body part position for installation.

Push the inner core to go through the nozzle than make the steel wire stretch on the outside of the nozzle, press them and fasten it well.

You could ask us for the datasheet of the armoured cable gland clamping range, then you could get the idea.

We could make any thread types according to customer’s requirement, such as PG, NPT, G, Metric etc.

We have both double compression and single compression functions in our armoured cable gland for your selection.

Our armoured cable gland size range from M20 to M110( G1/2 to G4)

Our amoured cable gland have Metric thread, G type Thread and NPT type thread as our customer’s requirements.

Yes, our armored cable glands waterproof grade reached IP66.

Our armoured cable glands could be fit for any cores number SWA cables, such as 4 core 16mm armoured cable gland, 10mm 3 core armoured cable gland, and 6mm 3 core armoured cable gland etc.

We must note the SWA cable inner diameter and outer diameter sizes in the gland clamping range.

Armoured Cable Gland Buying Guide

Armoured cable glands are vital armoured cable accessories, which seal and terminate cable connections.

In case you didn’t know yet, armoured cable glands serve as a secondary earth.

The armoured cable glands guarantee protection from:

- moisture and;

- dust

Armoured cable cleats support and safeguard armoured cable to a surface.

You see:

These are only the basic information about armoured cable glands.

There are much more you need to learn.

But how can you get them?

The good news!

In this e-book, we will present you all the information you need when it comes to armoured cable gland.

Throughout this post, you will understand the topics about:

- armoured cable gland definition

- armoured cable gland parts

- sizes and types of armoured cable glands and;

- how to install armoured cable glands

After this, you will be equipped on what armoured cable gland it, and its purposes.

Without further ado:

Are you now ready to get started?

So let’s jump right in!

Chapter 1: Armoured Cable Gland Definition: What is Armoured Cable Gland?

Did you know?

An armoured cable gland is a special kind of terminating cable glands.

These are created for wire braid cables applied in a hazardous region along with ATEX certificates.

You see:

Armoured cable diameter size is much larger compared to standard cables.

That’s mainly because of the armoured outer sheath and wires.

Thus, the size calculation in millimeters should be taken into consideration.

Armoured cable gland in telecommunication transmission box

An armoured cable gland is typically made of:

- stainless steel or;

- brass

They offer strain relief for the armoured cable.

You see:

That metal could guarantee your cable gland along with anti-corrosion feature.

That could make sure it will work in better condition in explosion-proof demand circumstances.

Beyond that:

The armoured cable gland kits assure the waterproof function will reach IP68 grade.

For example:

- earth tag

- lock nuts

- PV shrouds

that is very crucial for outdoor applications.

So, have we got that straight?

The thread types are accessible for:

- PG

- NPT

- Metric etc.

The cable diameter size ranges from 6 millimetres to 78 millimetres.

More about Armoured Cable Glands

The armoured cable connector is also called a grounding shielding connector.

You see:

Power lines transmit into the electrical cables and equipment mainly through the armoured cable joints.

It offers a better shielding effect once the armoured cable is grounded and the device is connected.

Some of its features include:

- the kit is composed of IP washer, locknut, earth tag, shroud, and gland

- accessible as a kit as standard

- suitable for both outdoor and indoor applications

- suitable for use in operating temperatures of -60 degrees Celsius to +150 degrees Celsius.

- offers mechanical retention, an earth continuity through armour wire termination and a weatherproof seal on the outer and inner sheath of the cable

- standard material is brass; but also available in nickel-plated brass

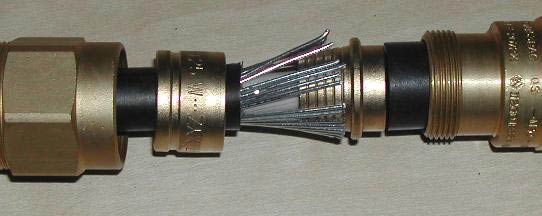

Armoured cable gland with entry cable

And another thing:

The armoured cable is an auxiliary and power control cable.

It is created for use in mains supply electricity.

In fact:

It is utilized for:

- cable ducting

- indoor and outdoor applications

- power networks

- cable networks and;

- underground systems

Chapter 2: Armoured Cable Gland Parts

When we talk about armoured cables, they do not need any special tools.

It could be cut along with a pair of quality wire cutters or with a hacksaw.

A pair of side cutters help cut the individual cores of galvanizing steel wire.

What’s more:

Two spanners of the proper size are required for the efficient fitting of armoured cable glands.

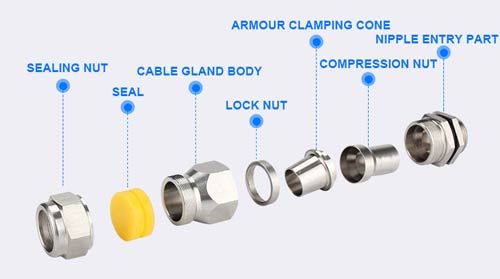

Armoured cable gland parts

Below are the parts for an armoured cable gland:

- sealing nut

- seal

- cable gland body

- lock nut

- armour clamping cone

- compression nut

- nipple entry part

Do you want to know their functions?

In this section, we will dissect their proper uses and role in the operation of cable gland:

Sealing Nut

Sealing nut

An armoured cable gland sealing nut is a small, hexagonal tool.

This is utilized mainly for safeguarding into position all kinds of cable glands and cables grommets.

Take note that this component is created to link and protect the end of an electrical cable to other equipment.

Some of its available materials are as follows:

- Stainless steel. It offers corrosion resistant along with raised strength at high temperatures

- This is recommended when installing aluminum armoured cable glands to avoid galvanic corrosion. That can happen when different metals are combined.

- Zinc plated mild steel. This is a cost-effective option to brass nuts. They must be utilized on in humidity, low and dry conditions.

Seal

A seal is a type of lock nut with a rubber collar insert which resists turning.

The rubber seal is located at the end of the nut, along with an inner diameter comparatively lesser than the main diameter of the screw.

Seal

The insert distorts elastically over the threads of the screw, with no threads in turn cut into it.

The rubber seal locks the nut through friction against the screw under the applied radial compressive force.

Armoured Cable Gland Body

Armoured cable gland body

The cable gland’s body, as well as housing, are normally made out of:

- plastic

- steel

- stainless

- steel

- aluminum

The housing and the body are composed of all other components of the cable gland.

Armoured Cable Gland Lock Nut

A lock nut is also called as flanged or flange nut with collar.

It is composed of a hollow cylinder having fine interior threads at one end for threadedly engaging a pump mechanical seal assembly.

Locknut

The flange has a big portion with a groove for getting an O-ring for sealing against the intrusion of pumpage from the exterior.

Armoured Clamping Cone

Clamping cone allows clamping of the square and round pipes by simply positioning them.

You see, a clamping cone is attached with bolts.

Armoured Clamping Cone

Compression Nut

Compression nut, on the other hand, is small, hexagonal devices.

They are utilized to securing into position each type of cable glands and cable grommets.

Compression nut

You see:

This cable gland parts are utilized in a wide array of industries which employ wiring and cable utilized in:

- automation and;

- electrical instrumentation systems

Cable gland compression nut might be utilized on each type of data & telecommunications cable, instrumentation, control, and electrical power.

Armoured cable gland earth tag

Armoured cable gland earth tag

Armoured cable tag earth tags are made of metal.

They are utilized for earthing metal glands.

You see:

They have a hole in the tag end for linking the earth conductor too.

Easy to use, simply slip on before installation.

Usually, when earthing an armoured cable, a few direct-to-ground external earth link cables are utilized.

It is connected to the cable via an earth tag.

As a minimum requirement, the cable will be earthen approximately one of its two ends.

That means, in the event of short-circuit or fault, the majority of a direct route to the ground will be obtained.

Chapter 3: Types and Sizes of Armoured Cable Glands

Did you know that there are various types of armoured cable glands?

In this section, we will distinguish them.

Steel Wire Armoured Cable Glands

B324 Zen Gland (insulated)

This armoured cable gland boasts a cast integral earth lug.

It allows the zoning of earth connections for earthed neutral systems.

B348 Zen Gland (insulated)

Brass insulated Zen cable gland offer an IP66 environmental seal on all steel wire armoured cable outer sheaths.

This glanding method insulates the cable armour and gland from the enclosure of the equipment.

E1WF Gland

This kit is specialized for use on SWA cables with ATEX Cat 2 and CAT 3.

It offers an IP66 seal on the outer and inner cable sheath.

E2WF Gland

Flameproof ATEX specialized brass armoured cable gland kit is ideal for lead sheathed SWA cables throughout zone 1 and zone 2 hazardous regions.

E1W Gland

The weatherproof armoured cable gland kit is ideal for all steel wire armoured cable types.

It offers an IP66 environmental seal on the outer and inner sheaths.

CW CIEL Gland

This gland boasts a heavy-duty cast integral earthing lug.

This is perfect for cases where a higher level of fault current protection is needed.

Particularly helpful in MV installations.

CW Gland

CW armoured cable gland

This armoured gland kit is ideal for outdoor and indoor applications on all steel wire armoured cables.

It offers an IP66 environmental seal on the outer cable sheath.

BW Gland

Brass BW armoured cable gland kit for indoor use.

This is ideal to be utilized on all steel wire armoured cable.

It offers mechanical continuity and cable retention through armour wire termination.

Aluminum Wire Armoured Cable Glands

A324W Zen Gland

This gland boasts a heavy-duty, cast integral earth lug.

That enables the zoning of earth connections for earthen neutral systems.

A348W Zen Gland

This is appropriate for outdoor and indoor installations.

It offers an IP66 seal on the outer sheath for every AWA armoured cables.

E1W Aluminum Gland

This is an IP66 weatherproof cable gland kit for use along with every AWA cables.

It offers an environmental seal on both the cable outer and inner sheaths.

Aluminum CW CIEL Gland

This gland kit along with cast integral earth lug is perfect for use with all AWA armoured cables.

It offers an environmental seal on the cable outer sheath.

CW Aluminum Gland

Aluminum outdoor and indoor armoured gland kit ideal for all AWA single core cables.

It offers an IP66 environmental seal on the cable outer sheath.

Steep Tape Armor, Steel Wire Armor, and Wire Braid Armoured Glands

ICG / 653 / Universal EExd Barrier Gland

IP66 rated, this is a dual-certified brass Hawke barrier gland.

This is ideal on STA, SWA, and Wire Braid armoured cable glands.

It features a compound seal area and deluge boot, safeguarding the gland-mating thread.

501 / 453 / Universal Gland

Dual certified IECEx / ATEX brass weatherproof gland.

This features a universal armour clamp for use with SWA, wire braid, and STA cable types.

153 / RAC Gland

Brass Hawke armoured gland is offering an IP66 environmental seal on the outer and inner sheaths.

This reversible armour clamp makes the gland perfect for use with all cable types.

PX2K Explosion Proof Submersible Barrier Gland

Gas-tight, flameproof, brass, compound filled cable gland, ATEX rated for use in CAT 2 hazardous places.

It offers a gas-tight compound barrier around your cables cores.

It also gives an IP66 seal on the outer sheath.

TRITON Submersible Gland

This gland offers a one-of-a-kind idea in sealing methods.

It integrates the patented compensating displacement seal system.

Along with LSF sales within, TRITON gland is ideal with all cable types (wire braid, STA, SWA).

E1XF Gland

Flameproof ATEX certified brass armoured gland kit is ideal for all types of wire braided or STA cables in the zone and hazardous zone regions.

On the other hand:

The series of armoured cable flameproof sealing joints are divided into two types:

- Type I and;

- Type II

Type I is an external thread at one end, and the other end is clamped.

Type II is externally threaded at one end and internally threaded at the other end.

The connector body also prevents the cable from being pulled out by clamping.

Also, two elastic sealing pads are installed to lead the cable out and block the entry and exit of the explosive gas.

It is mainly used in the introduction of rubber cables and plastic cables with high requirements for explosion-proof technology.

There are two structures: I and II

Among the series of isolated explosion & seal joint with armoured cable.

I tape: one end is an external screw, the other clamp.

II tape one end is an external screw.

The other internal screw.

The body has a clamp, which can prevent cables from being pulled out.

Two elastic & sealing filler strips are fixed inside.

That can make cables spread out and separate exploding gases from going in & out.

The structures are mainly applied in the rubber & plastics cable devices Where explosion-proof technology is of high requirements which are marked with Exd IIC.

The material of the explosion-proof sealing joint is:

- copper alloy

- nickel-plated brass, and;

- stainless steel

Because of the excellent thermal conductivity of copper and high-quality stainless steel and almost no carbon, the heat generated in a short time is absorbed when the joint rubs or affects with the object.

Conduction is another reason due to the relatively soft copper and stainless steel itself.

Good confinement in friction and impact since it’s not easy to produce tiny metal particles.

Therefore, you can hardly see the spark, so to achieve the effect of explosion-proof.

The main scope of application is:

- petroleum refining and petrochemical industry

- coal mine

- oil field

- the natural gas chemical industry

- chemical fiber industry

- paint industry

- fertilizer industry

- various pharmaceutical industries

- oil wheels and LPG vehicles

- warehouses for flammable and explosive products

- electrolysis workshops

- communication machine assembly workshops

- places where joints are not rusted, wear-resistant and diamagnetic

Chapter 4: Armoured Cable Glands Installation: How to Install Armoured Cable Gland Fitting

In this section, we will teach you how to install an armoured cable gland fitting into a wire properly.

Take note:

The role of armoured cable gland is to hold the wire.

It also stops it from being pulled off the appliance and serves as secondary earth.

The first thing you need to do is to fasten dual glands into a waterproof box for some external lights.

Then, choose a hole saw.

That saw must be big enough for the threaded portion of your nozzle to fit through.

Then, drill a hole in your box, do this on a very slow pace.

The second step:

You need to push the threaded portion of the nozzle through the earth tag.

Push that through the hole, which you have just created.

Screw the nut on the inside of your box to hold the nozzle in place.

The third step:

You need to utilize a spanner to grasp one nut.

Do this while you are turning the other nut along with additional spanner.

Take note:

You need to make sure that the nuts are always tight.

However, do not tighten them too much as well.

The fourth step:

Now that you already fastened the nozzle securely to the adaptable box, what’s next?

It is now the time that you need to prepare your cable.

It makes sense to place the parts on the cable before you begin cutting it.

That’s mainly because the steel wire often makes it complicated to slide the components over.

Therefore, what should you do?

Cut the end of your protective cover and slid it onto the wire.

Just make sure that it is facing the right way!

The fifth step:

For the fifth step, slid your nut that contains:

- the collar

- the rubber sealing ring and;

- the nozzle nut

onto the cable.

That can be pushed now back far enough so that cutting the wire is simple.

The sixth step:

The outer protective sheath requires getting rid of exposing the:

- galvanized steel wire and

- inner cable

You can complete t by using a knife to cut and get rid of the protective sheath.

For the seventh step:

In this section, you can now notice that the outer insulation has been eliminated.

It will now expose the galvanized steel wires.

For the eighth step:

Here, the separate steel wires now require dividing to a length.

You need to do this so that they fit into the nozzle that you fastened into the box.

You can utilize side cutters for performing this.

However, the majority of expert electricians utilize a hacksaw.

If you use it, you can score the steel wire lightly.

It can bend back and forth to break it off.

On the other hand:

Side cutters can only be utilized on this thin SWA cable.

That’s because the end is squeezed when cutting.

If you are in doubt, you can freely utilize the hacksaw technique.

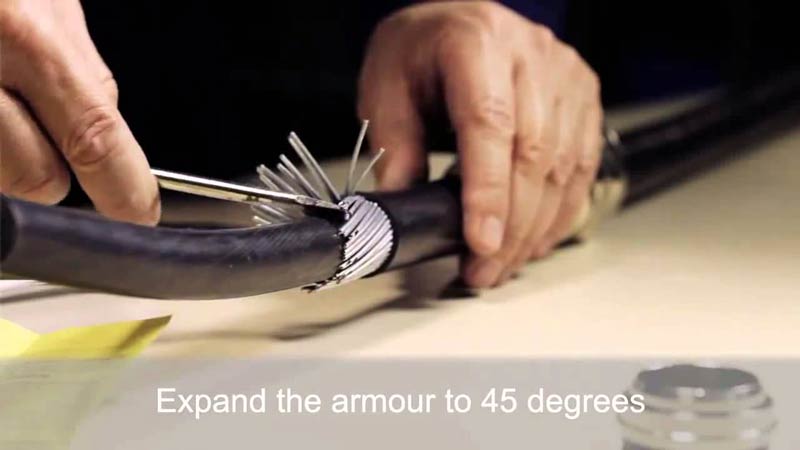

For the ninth step:

The steel wires require flaring slightly.

It’s not simple to manipulate an SWA cable.

However, with practice, this is perhaps simple.

But for those DIY-ers who utilize armoured cables rarely, it can be complicated.

For the tenth step:

Push your wire, so the inner core goes through the nozzle.

It will flare out the galvanized steel wires, so they’re on the outside of the nozzle.

Then, push the collar confidently over the wire.

That must grip the wires and can be tough.

For the eleventh step:

Slide up your collar nut and squeeze it by holding the nozzle with 1 spanner and the collar nut along with another spanner.

This requires to be as tight as possible with no stripping the treads.

For the twelfth step:

Now, you can slide up the nut that includes the rubber seal.

Tighten that nut to the back of your nozzle nut.

Again, that should be tight, and two spanners are required.

That nut has a rubber seal that grips the insulation on the cable.

You see, that’s the key to making a watertight seal.

For the thirteenth step:

Slide your protective cover on the gland.

You have now successfully terminated a wire at a box.

Earlier, we have mentioned about armoured cable glands being utilized for continuity of earth.

It is essential that you have drilled a hole through the box that aligns with the hole in the earth tag.

It’s also vital that you marked a hole in the middle of where the second gland should be located.

That way, all you need is to attach a rustproof bolt through the hole and constrict it for continuity of earth.

On the inside of your bolt must be earthed to the current earth wire.

You can achieve this by utilizing a suitable crimp connector.

Both glands are attached securely and offer continuity of earth along with the bolt, which connects the 2 earth tags.

Take note:

The bolt should be rustproof and tight.

Conclusion

Similar to other types of cable gland, armoured cable gland is very essential.

Take note:

Cable glands are designed to be employed on armoured or non-armoured cables.

It should be highlighted that it doesn’t matter which type of cable gland is utilized or how much it costs.

Your cable gland should be fitted always in accordance with the instruction of the gland manufacturer.

There you have it!

These are only the essential information you need to know about armoured cable glands.

What are your thoughts about this post?

Share your ideas with us by leaving your comments.

Do you have queries about armoured cable glands?

Feel free to get in touch, and we will be happy to answer them for you.