Cable Gland Manufacturer in China

We have been one the professional manufacturers of various sizes of cable glands in China for more than 20 years, send us your inquiry for an expert reply soon.

The cable gland is a device that provides strain relief and sealing protection for the electrical cables throughout.

There are many types of threads of the cable glands such as PG, Metric, G, and NPT, all sizes are available for the short thread and long thread as customers need.

Cable glands also named cord grip, strain relief, cable gland connector, and cable fitting, are widely used in many industrial fields such as industrial machines, electrical equipment, telecommunications, and new energy appliances. The cable glands are widely applied in harsh environments with heavy pollution elements such as oil, dust, and moisture, so their sealing protection grade IP68 & IP69K is significant to ensure the equipment’s inner space without influence.

The cable glands were classified into different types according to different functions: Waterproof cable gland, armored cable gland, explosion-proof cable gland, EMC cable gland, double compression cable gland, single compression cable gland, etc.

We could design and manufacture all of the cable glands for any special requirement from our customers. The quotation will be provided for you in 3 working days after we receive your drawings and detailed datasheet.

If you are sourcing for world-famous brand cable glands, such as Hummel, Lapp, Peppers, and CMP, we can copy these items for you according to your drawings and samples. The price will be very competitive in your market.

If you are a famous brand in your market and want to seek an OEM manufacturer in China, we will be your first selection. Send your inquiry now!

CEO Notes

Hey, Thanks for visiting our website, and I hope to be a friend to you here. As one of the top cable gland manufacturers& Suppliers in China, we are manufacturing different types of cable glands for our customers around the world. Our company also provides OEM service as one of your potential suppliers for your customized order. Thanks!

Questions You May Ask About Our Cable Gland

We could provide all of the different function cable glands for our customers, such as waterproof cable glands, armoured cable glands, double compression cable glands, explosion-proof cable gland, etc.

Our cable gland could reach IP68 and IP69K waterproof grade.

Cable glands play a relatively large role in industrial applications. Some of the main application areas are:

1. Main connection of electrical equipment.

2. the connection of system engineering.

3. Application of solar energy technology.

4. Application of decoration technology.

5. The establishment of the power system.

6. Outdoor lighting, for example, LED street light power cable connector line.

7. Engineering and marine navigation applications.

8. Other applications of cable glands: motors, automated instruments, telecommunications installation, medical monitoring, etc.

We have IP68 certificate, ATEX certificate, CE

In China custom, the manufacturers normally show the cable gland HS code as 8547901000.

Cable Gland: The Helpful Guide for Importers

There are lots of growing massive use of cable glands in the office and home as well as the several industries across the world today.

Such create the basic wire management products that are very convenient and functional in many homes and industry needs.

Even though there might be other sorts of wire management products like:

- clamps and clips

- plugs

- connector caps

- tapes and tubing

- bushings

- panel plugs

- grommets

a cable gland is always a sought-after option.

In this e-book, allow us to present you the information you need to know about cable glands.

Are you now ready?

Let’s get started.

Chapter 1: Cable Gland Definition: What is a Cable Gland?

Cable glands are tools which are essential when terminating cables in harsh or hazardous environments.

These are settings where grounding, sealing and ingress protection is vital to pass a cable safely.

They offer strain relief and are made to include electrical flames or sparks which might happen in a hazardous setting.

In case you didn’t know yet, a cable gland also serves as a seal, blocking outside contaminants from causing any damage to the electrical and cable system like:

- fluids

- dirt;

- dust

Ultimately, they avoid cables from being pulled out or twisted out of the machine.

That’s because they help to offer a secure connection between the machine and cable to which it’s connected.

You see:

These devices are made for use with either non-armored or armored cable.

If utilized with armored cable, they offer a ground to earth for the design of the cable.

Cable glands could be made for both non-metallic and metallic based materials.

Different infrastructure based sectors employ them as part of their wiring and cable-based requirements.

That’s particularly in instrumentation which is automation and electrical tool.

Cable glands are circuitous mechanical cable entrance elements which aid join and close electrical cable which goes into a:

- generator

- pump

- housing

- motor

Those glands are wide-ranging solutions for a more expensive course.

They are employed worldwide over huge and millions of applications.

You can employ any electrical power, for data and communicable cables, in instrumentation and the like.

They are also utilized to close up a device when a cable has been passed through it for security purposes.

Cable glands used in automation equipment

When it comes to the type of materials as well as their grading, cable glands could come in:

- aluminum

- brass

- plastic;

- stainless steel

utilizing for several reasons is vital.

You can link a cable to a piece of equipment and be certain which is secure.

They help in keeping what is called ingress protection.

They aid in the earth or grounding continuity of the equipment which they’re attached.

Because these are flameproof, they’ll be able to endure and cover any explosion which happens internally.

Each place has its code of standards which is utilized to identify the quality.

You need to ensure that yours qualifies the test.

If you’re selecting a cable gland, you need to ensure to consider different factors.

Remember, there’s some electrolytic action which happens when two different materials come together.

It will bring down the sturdiness of the glands.

The appropriate number of ingress protection is needed.

The piece needs to be certified for use in harmful environments.

Different cable gland manufacturers around the globe are making such glands using various materials.

Among the metal items, the production of cable glands through brass is frequently utilized these days.

Cable Gland Specification

When choosing a cable gland, you will find various steps to take to guarantee the ideal cable gland is utilized in your application.

The initial step is to determine the type of cable to be utilized and then check the material, size, and construction of the cable.

Important cable gland specifications to consider when looking for cable glands include:

- adjustable diameter

- mounting hole diameter

- cable diameter

Following are the specs you need to take into account:

- The modifiable diameter is the diameter the cable gland can be attuned to suit different sizes of cable.

- Mounting hole diameter is the diameter of the bulkhead hole or barrier into which the cable is to be installed.

- The cable diameter refers to the diameter of the cable which can be fed inside the cable gland.

- The amount of wires the assembly can house is crucial to consider.

- Pressure rating means the number of pressure a tool can endure without any leakage.

- Wire hole diameter is considered as the maximum diameter of a wire or cable.

This must be big enough to accommodate all the cables within the system.

Materials of Construction

The material is very crucial specification when choosing a cable gland.

The typical material types accessible are:

- stainless steel

- brass

- PVC

- nylon

- aluminum

It must be compatible along with the cable material to avoid damages, excessive wear or corrosion.

Mounting Options

Cable gland mounting must be selected according to the pre-existing connections within the system.

Options for gland mounting include:

- compound or adhesive

- bolted or flanged

- nut mount or threaded

- cast

- welded

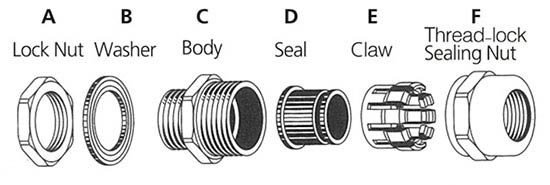

Cable Gland Parts Name

If you want to know the different parts of cable gland, you must first know that there are single compression cable glands and double compression cable glands.

Both have different parts.

1. Single Compression Cable Gland

Single compression cable glands are utilized for those lightly armored cables.

With this cable gland, there’s no cone and cone ring.

Single compression cable gland parts

Parts of single compression cable gland:

- Flat washer

- Neoprene rubber seal

- Check nut

- Rubber washer

- Body nut

- Gland body

2. Double Compression Cable Glands

On the other hand, double compression glands are utilized where big armored wires are getting out or coming into the board.

These cable glands offer further assistance to the big armored cables.

Parts of double compression cable glands include:

- Check nut

- Rubber washer

- Neoprene rubber seal

- Cone ring

- Cone

- Body nut

- Gland body

Chapter 2: Cable Gland Working Principle: How Do Cable Glands Work?

Did you know that cable glands are utilized to remove electric cables to electrical enclosures or electrical equipment?

For most electrical installations, they are necessary to be fitted.

The type of cable gland chosen will be dependent on a series of factors:

- Cost

- Corrosive atmosphere

- Explosive atmosphere

- Outdoor or indoor environment

- Type of installation: industrial, commercial or domestic

Why Cable Glands Are Used

With badly handled electrical installations, you are aware of the repercussions very well.

For instance, electrical fires wherein your lives are at great risk.

Exposed ends are a big no-no too.

That’s true whether you’re dealing with optic wiring or electrical cables.

Now, that’s where cable glands do a pivotal role.

As you can tell, cable glands are utilized to protect and connect the end of every cable to telecommunications or electrical equipment.

Cable glands applicated in electrical enclosure

They offer connections and relief using which is appropriate for cable types as well as their applications.

For instance:

- Control systems

- Instrumentation

- Data communications and;

- Electrical power lines

In the US, cable glands are referred to as fittings or cable connectors.

Cable glands are typical household tools or any environment which utilizes equipment and appliances which need supply electricity.

These products might be exposed to destructive elements such as dirt or water which could disable some delicate electronics.

That’s where cable glands can be utilized as well.

Its role is to seal off cables and wires passing via electrical enclosures for the preferred, excellent protection.

Furthermore, cable gland provides a massive strain relief.

Therefore, they work outstandingly to their function.

Those thick enclosures enable simple threading.

Meanwhile, metal enclosures along with thin sheets could utilize the gasket or locknut for a quick sealing.

Quality glands along with the IPR68 standard guarantee optimal performance along with extended durability compared sub-standard ones.

Replacement is easy and low with accessibly of the appropriate models available within the market.

Each quality piece offers its approval to function efficiently.

There’s a variable clamping range for accommodating all kinds of cables along with numerous sizes.

Take note:

The ideal functional cable glands are those which have the minimum of maximum clamping range.

They must be capable of functioning at particular temperature ranges like -40° Fahrenheit to 221° Fahrenheit or as extreme as 149° Celsius (300° Fahrenheit).

On the contrary, silver or gray cable glands offer optimal performance in water and dust tight settings along with better strain relief.

That would make sure a much longer functionality of the bigger and more overpriced equipment in the industry or home.

Cable glands are no doubt a dependable, economical way of safeguarding machinery from:

- debris

- water;

- dust

The durability of such items is obvious as they’re employed by:

- marine systems

- solar energy systems

- HVAC systems

- exterior lighting systems

- fluid control systems

Even though such items serve as enhanced added security for equipment in any case, for optimum results, you must choose a cable gland with the least maximum clamping range for the specific application.

Doing this will make sure that costly equipment is as safe as possible.

That’s thanks to the tightest seal.

Where Cable Glands Are Used

As mentioned earlier, a cable connector or cable gland is a tool made to connect a cable into an electrical device which offers:

- insulation

- retention

- sealing

- support

- shockproof and;

- earthing

The cable glands could be fitted on any types of cable like:

- data cables

- telecom cables

- equipment connections and;

- power cables

They are utilized as a sealing and termination device.

Cable glands used in electrical distribution box

It guarantees that the cable must not get detached from the main circuit.

There’s always a demand for cable glands.

It could be the office, home, industrial or any property in any setting which needs such objects.

Household Applications

Cable glands are typical household items.

They can be used in equipment of appliances which need an electricity supply.

Wires might be susceptible to destructive elements such as dirt or water which could incapacitate some delicate electronics.

That’s where cable gland use can be utilized to seal off cables and wires which passes through electrical enclosures.

Industrial Applications

Cable glands are widely used in industrial applications as well.

Such glands are considered mechanical cable entry devices.

They could be made from non-metallic or metallic materials.

Cable glands used in machine

It offers strain-relief and links using suitable for a particular kind and description of cable for which it was made.

It covers the provision for creating electrical connections to the braid or the armor and aluminum or lead sheath of the cable.

Aside from home and industrial use, cable glands can also be employed in different industries.

Some of these include:

- telecommunication cable

- instrumentation

- data

- control and;

- electrical power

They can also be utilized as a termination or sealing devices to make sure that, attributes of the enclosure through which the cable go in could be kept.

Other Applications

Telecommunications Gland

This is made for use with conduit or communications cable.

Railway Gland

Made for use on trains and other installations.

Utility and Power Gland

Made specifically for public utility equipment like high voltage equipment, distribution, and power transmission.

Enclosure or Panel Cable Gland

These are rated and designed for penetration into electromechanical assembly enclosures and/or electrical panels.

Marine Gland

These are designed for applications on drilling, offshore mining settings, ships or many marine applications.

Fire Protection Gland

Rated and designed for the anticipation of fire spread across the barrier or bulkhead.

Industrial Gland

As mentioned earlier, this is utilized in industrial settings like mills, process plants, factories and so on.

Cleanroom Cable Gland

Ideal for use in a cleanroom setting along with the associated properties of keeping positive pressure, the anticipation of fluid ingress and dust, etc.

Aerospace Cable Gland

Rated and made for use on space or aircraft vehicles and equipment.

It might cover applicable approvals for aircraft use and military use.

Why Cable Gland Earthing Is Required

Electrical continuity is typically accomplished through the screwed entry onto metal boxes.

When there’s a clearance hole entry scenario, it’s crucial to get direct metal-to-metal contact among the glands.

Thus, an earth tag is employed between the enclosure and the gland.

The usage of armoring alone as the sole earthing isn’t suggested for cases where there’s a necessity for positive earthing because of great possible currents.

A series of integral earth glands are accessible.

Cable gland earthing

On the other hand, insulated adaptors are accessible for installations where it’s needed to prevent connection among the earth and cable armor at one end of the route.

An example of this is the break within the earth loop which can produce false signals.

Direct to Ground Earthing

Whenever earthing an armored cable, a series of direct-to-ground external earth link cables are employed.

They are linked to the cable gland via an earth tag.

You see:

The cable will be earthed roughly one of its one ends as a minimum requirement.

That means in the event of a short-circuit or fault, the most direct way to ground will be accomplished.

‘Daisy Chain’ Earthing

When multiple cable entries are needed in a non-metallic device enclosure, this earthing method could be applied,

An external earth cable is linked to an earth tag in every cable gland.

It should be at least one earth tag utilized to link the earthing cable straight to the ground.

Chapter 3: Cable Classification: How Many Types of Cable Gland?

Various cable requires various types of cable glands.

In case you didn’t know yet, cable glands types are divided into different categories.

They are divided into:

- according to material

- according to thread type

- according to applications

- according to characteristics

- according to compression types

Different Types of Cable Glands

According to Material

- Stainless steel cable gland

- Brass cable gland

- Nylon cable gland

- Aluminum cable gland

According to Thread Types

- PG thread cable gland

- Metric thread cable gland

- NPT thread cable gland

- G series Cable gland

According to Applications

According to Applications

- Waterproof cable gland

- Flameproof cable gland

- Explosion proof cable gland

- Strain relief cable gland

- EMC cable gland

- Armored cable gland

- Unarmored cable gland

According to Compression Type

Single compression cable glands

Single compression cable glands are utilized for lightly armored cables.

In case you didn’t know yet, normal cable gland is also termed as Single Compression.

As you can tell, while you stiffen the gland, the compression or grip is influenced only in one area.

For example, at the cable armor exclusively.

There’s a scope for corrosive and moisture vapor to reach the gland and therefore to the cable.

Double compression cable glands

This offer added support to the bulky armored cables exiting or entering the panel.

However, in a double compression cable gland, the compression occurs both at the inner sheath and cable armor.

This is 2 sealing.

Therefore, the likelihood of vapor or moisture entry is lessened.

Such glands are also referred to as the Flame-Proof Cable Glands or Weather-Proof Cable Glands.

The only fundamental difference between the two is that there are no cone ring and cone, as mentioned earlier.

Chapter 4: Cable Gland Size Calculation: How to Select Cable Gland Size?

When we talk about installing cable gland types, it is crucial to prepare enough.

This is to avoid any accidents and the associated stress.

This is composed of the selection of the appropriate types of ss cable gland for the project.

You see:

The last thing which you like is to have the wrong cable fitting when the project is about to reach its conclusion.

The ideal time to choose the cable gland size to be utilized must be during the planning phase.

It will remove the hassle of identifying the cable gland sizes if the project is on its conclusion.

When choosing the idea cable gland selection with cable size, you need to remember two things.

First, you must identify the kind of cable you want to utilize for your project.

Then, it’s valuable to factor in the size, construction and the materials utilized on the cable.

When the project at hand needs the help of armored cables, then you need various factors to be accounted.

You need to check the type of the cable armor as well as the material utilized in manufacturing it.

You also need to check the short circuit fault current rating of the cable.

It also includes the lead covering, the diameters of the inner bedding, and the entire cable itself.

You also need to know whether you will require a cable gland with protective plating or corrosion protection.

This is suitable for use in regions with particular environments.

You must also check the materials utilized in the mating electrical enclosures.

Keep in mind that employing mismatched metals can result in massive side effects.

Furthermore, you also need to check the entry hole of the cable.

This includes the size and type in connection to the electrical device where it’ll be connected.

Other crucial things to consider include the:

- entry thread seal

- shrouds

- earth tags

- weather accessories such as washers and locks nuts are to be utilized

- whether reducers, stopper plugs, and adapters are needed.

It is essential to do your research earlier of the actual installation of your cable glands.

It will enable you to prevent the stress of picking the wrong plastic cable gland sizes.

It will also permit you to facilitate the fast completion of the installation.

What’s the next thing you need to do when the installation is finished in high-risk regions?

Well, prevailing industry, national and international safety standards must be adhered to prevent any unforeseen incident.

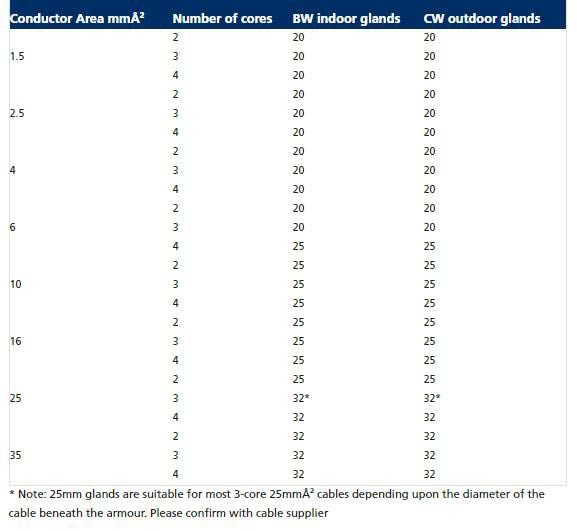

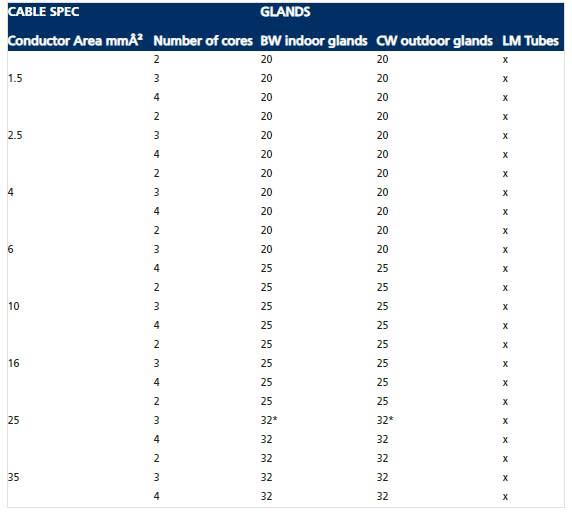

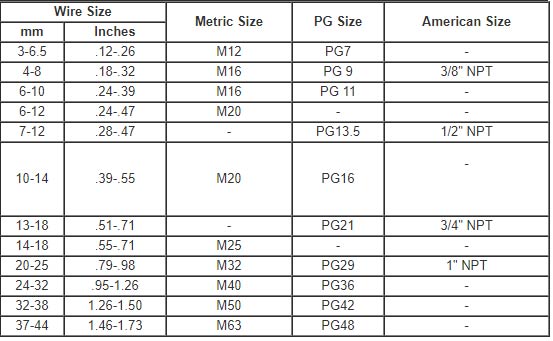

Cable Gland Size Table

When we talk about cable glands, the approach “one-size-fits-all” won’t be effective.

You need to bear in mind that different equipment and industries have its own set of requirements and following parameters.

Do you want to make sure the safety of your equipment and to comply with the right standards?

If so, you need to utilize the appropriate brass cable gland size according to its application setting.

The table below is a guide to proper cable gland for a specific cable.

However, the individual application might need different glands.

So make sure you confirm along with the cable supplier.

Photo Courtesy: Lucy Zodion

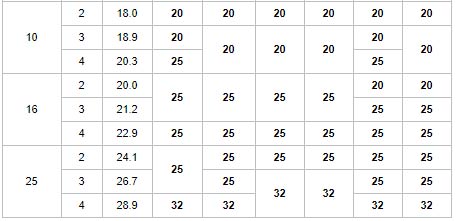

Cable Gland Selection with Cable Size

Other crucial criteria for the selection of glands are the entire diameter which the cable gland should accept.

It must continue to offer a strain relief and a protected interface between the inside and the outside of your equipment.

Cable glands are typically rated for a maximum and minimum cable diameter.

An example of this is 13 millimeter to 18 millimeters.

When the cable is quite smaller than average, then you will have the option of choosing a lowered cable entry version of your cable gland.

Ultimately, when various cables are to feed via a single cable gland, then it might be feasible to utilize a plug or multi-entry seal.

Cable gland size chart

Various Type of Cable Glands and Size

As mentioned in the previous chapters, there are different types of cable glands.

Therefore, you can expect that this cable gland has different sizes too.

In this section, we’ll briefly differentiate the type of cable glands and their sizes.

Let’s begin:

1. For Brass Indoor Type Gland

This kind of glands can be utilized with a plethora of types of wires like plastic, steel, and rubber.

Application could be anywhere between Dry Indoor and for use with every type of SWA Cables:

Cable Type: steel wire armor

2. For Brass Outdoor Type Gland

This cable gland is widely utilized with a single wire armored.

It’s recommended to utilize PVC shroud for added ingress protection.

Cable Type: Wire Braid Armor

Application: It is most suitable for plastic of elastomeric sheathed cables and SWA

Size of the Gland: 20 millimeters to 75 millimeters

3. For Brass Straitening Unarmored Cable Glands

These are chrome and nickel finish glands which are utilized with a wide array of rubber sheathed cables.

Application: Ideal for indoor and outdoor use, along with every type of unarmored cables

Cable Type: Unarmored

Accessories: Shroud Brass Weather Proof Gland, PVC Washer, Neo Prime & LSF Rubber, Earth Tag, Brass Lock Nut

Size of the Gland: 20 millimeters to 75 millimeters

4. For Brass Weather Proof Gland

These are nickel and brass finish cable gland provided for environmental.

It seals in the outer cable sheath.

It’s perfect for rubber and SWA sheathed cables.

Application: Indoor and outdoor, use with single armored

Cable Type: Steel Wire Armor

Size of the Gland: 20 millimeters to 75 millimeters

5. For PG Threaded Gland

Such cable glands provide fast and added protection in different industries sector.

In case you didn’t know yet, this sort of PG cable glands is very simple and hassle-free to use.

It offers an excellent strain relief as well as a watertight seal for those round cables.

Accessories: Adaptors, Reducers, Earth Tags, Lock Nuts, PVC Shrouds

Standard: EN 50262:1999

Size of the Gland: PG 7 to PG 48

6. For Industrial-Type Gland

This cable gland is intended to terminate cables efficiently into industrial enclosures.

It offers a weatherproof seal into the cable

Armor Clamping: 3 Part with Lock

Cable Type: Wire Braid Armor

Cable Gland Dimensions

You need to remember that cable gland dimensions vary from one manufacturer to the other.

Therefore, a thorough and detailed manufacturer selection also becomes crucial when choosing cable glands.

Cable Gland Pg to Metric Conversion

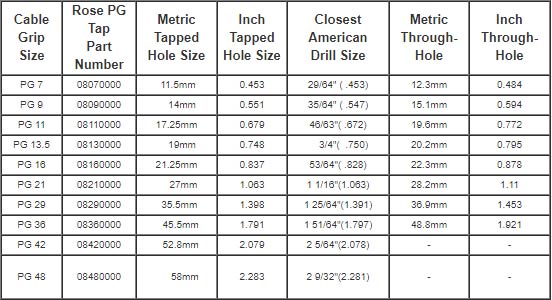

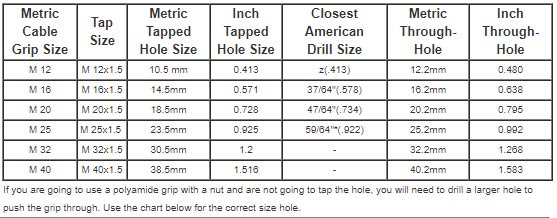

In the list below, you will find the essential information for tapping and drilling holes for PG or metric cable grips as well as the necessary tap part number.

Remember, thick wall applications needed that you tap hole for your cable glands.

On the other hand, thin-wall applications might be drilled with a nut.

Cable Grip Selection Guide

Cross Reference Chart

Cable Gland Hole Size

Cable Gland and Cable Size

If you undertake an electrical task, one of the major consideration is what size and type of cable to employ.

Choosing one which is too small for the project might lead to the danger:

- damaging the equipment because of the voltage drop or;

- melting the cable insulation

You need to remember that cables come in two major types:

- stranded conductors and;

- solid conductors

Solid conductor cables are reserve typically for the cables installed in industrial and domestic establishments.

It’s not flexible as standard and thus never be utilized where movement or vibration could obstruct the cable.

What’s more:

Copper work hardens with flexing becoming brittle.

Later on, it will crack, making a higher resistance at the fracture point.

It could result in overheating.

On the contrary, standard conductor cable is also termed as “cord” in the USA and “flex” in the UK.

It’s made of dozens of thinner threads of solid copper conductors.

Such thin diameter threads enable the cable to stretch effortlessly and slide over one another inside the PVC insulation.

Thus, the stress and bending forces are lessened.

Nevertheless, frequent bending will ruin the cable in the long run.

It might cause the single strands to break in the cable.

It will decrease the overall cross-sectional area and the capability to bring its rated current, making a hotspot.

If you want to know the proper size of cable for your cable gland, there are two things you need to remember.

The first is the load which the cable needs to supply.

The second is the length of your cable.

These two have an impact on your cable size.

Moreover, the selection of cable size will be based upon these factors:

- short circuit rating

- voltage regulation

- current-carrying capacity

Such factors must be assessed before you choose a cable size.

In most cases, short circuit rating and voltage regulation are ignored.

This oversight could lead in danger to personnel and property.

Short Circuit Rating

The cable size chosen must be assessed for short circuit withstand capability.

It must be based on the circuit opening period for the short circuit condition.

In short, the cable must hold with no thermal damages.

Voltage Regulation

In properly built electrical power systems, the voltage regulation is typically not an issue.

Voltages drop for extremely long runs at very low voltage.

Currency Carrying Capacity

This is based upon the thermal heating.

It’s also based upon particular spacing to allow thermal dissipation.

When this spacing is a bit smaller where the cable will be installed, then the derating of the cable is needed.

Chapter 5: Cable Gland Installation Guide: How to Install Cable Gland?

The gland size or entry thread connects to the threaded part of the cable gland.

It feeds via the sidewall of your pane or equipment.

Even though there are other kinds, the most sought after are the metric thread and PG cable glands.

The cable gland could be threaded into a tapped and drilled hole.

They can also be fed with a clearance hole, and a lock nut used to the threaded part which ranges into the panel.

A lock nut isn’t needed when using a threaded hole.

However, a lot of customers will utilize them for an added degree of security.

Extended thread versions are accessible for:

- where it’s needed to guarantee sufficient room for a lock nut or;

- enclosures which have special needs because of thickness

Cable Gland Installation Procedure

When we talk about cable gland installation, it should be carried while following the necessary:

- local regulations

- codes of practice and;

- by brass cable gland manufacturer guidelines

Installation must be carried out only by an experienced and qualified individual.

He or she must possess the necessary skills and knowledge in the installation of cable glands.

By the above, this cable gland installation instruction will help you.

It will guarantee that the installation of your cable glands will have a reliable and safe connection.

- Care must be taken to prevent any damage to the entry threads every time to install and handling the cable glands.

- Don’t install the cable glands while the circuits are live. After you energize the electrical circuits, your cable glands shouldn’t be opened or dismantled until the circuit has been de-energized safely.

- The components of cable glands aren’t interchangeable along with those of other cable gland companies. Components from one plastic cable gland manufacturers can’t be utilized in that of another. Doing so will impact the safety of your installation. It will also invalidate any blast protection certification.

- Care must be taken to prevent exposure of the gland sealing rings to chemical substances, dirt, and other foreign bodies.

- Cable gland sealing rings are covered in the cable gland if transmitted from the factory. There must be no cases where the sealing rings should be eliminated from the gland.

- A cable gland isn’t a user-serviceable item. That means spare parts aren’t allowed to be supplied for items that have been put into service.

Cable Gland Installation Instructions

Here is the installation instruction of your cable gland.

- Push the cable through the diaphragm seal

- Pre-fitted cable guide could now be rejected

- The diaphragm seal could be rolled back to ease assembly when needed.

- Spread the braid or armor over the diaphragm seal until the end of the braid or armor is against the shoulder of the armor cone.

- Place the armor clamping ring.

- Position the entry and position over the diaphragm seal.

- Adjust the sub-assembly to reach the entry.

- Hold the entry in position along with a wrench or spanner to avoid rotation.

- Hand tighten the middle nut to the entry and turn extra ½ to ¾ of a turn with a wrench or spanner.

(It’s very crucial that you support the cable to stop it from twisting.)

(If you want to ease wiring within the enclosure, it might be advantageous to strip the inner sheath of your cable.)

- Unscrew the middle nut and check that the braid or armor has been clamped successfully between the armor clamping and diaphragm seal.

- When braid or armor isn’t clamped, you need to do the assembly again.

- Reassemble the middle nut into the entry component.

- Make sure that you tighten up the middle nut ‘till handing tight.

- With the use of a spanner or wrench, turn the nut via ¼ turn.

- Tighten the back nut to create a seal within the cable, then tighten it further full turn.

- Make sure that the middle but doesn’t rotate when you tighten the back nut.

(Take note that the deluge seal on this cable glands locates on the assembly.)

(It needs no further action.)

(You can locate the shroud over the cable gland, if necessary.)

How to Fix Cable Gland?

For Standard Connectivity

- Stripped cable sheath & shield

- Outside of the circle with the discretion of retaining layer cut at least 15 millimeters

- Out of cable waterproof cable gland

- Eliminate the outer sheath

- Pull the cable, so there will be contact with cable shield reed

For Thin Metal Wire Without a Layer within the Nursing

- Stripped cable sheath and shield

- So that much outside nursing shield layer grew at least 15 to 20 millimeters

- Cable out of the cable gland, so contact with the cable shield reed contact

For the Cable Shielding Wire Connector that Should Be Linked with Other

- Uncovered shielding layer of at least 10 millimeters

- Cable out of the gland, so contact with the cable shied reed contact

Conclusion

Cable glands, like the majority of electrical components, are considered to be application-driven.

Thus, you must be thorough enough in the selection process.

Bear in mind that considerations should be given to:

- types of material

- level of protection

- associated gland

- size of the cable

- method of installing, and

- a wide array of other criteria

The great news!

A lot of PVC cable gland manufacturers and cable gland suppliers today provide a wide range of selections.

They have also developed their own online selection tools which help customers like you in making the right decision.