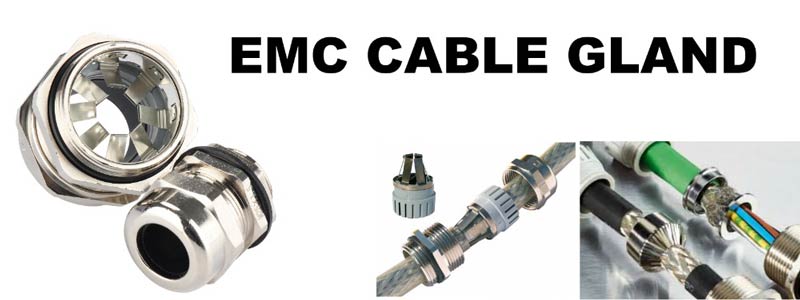

EMC Cable Gland

The EMC cable gland means the cable gland with Electromagnetic Compatibility, it has the ability of a device or system to operate in its electromagnetic environment without causing unacceptable electromagnetic interference to any device in its environment.

EMC cable glands contact the cable shield, compress the cable seals and provide electromagnetic(EMC) protect the throughout cables and the equipment at the joint point.

EMC cable gland normally made by the materials in stainless steel or brass, it provides ideal strain relief function, easy for installation and long and short entry available for customization. The thread type could be PG type, metric type and NPT type as customers need, all types of cables are in the clamping range of our cable glands.

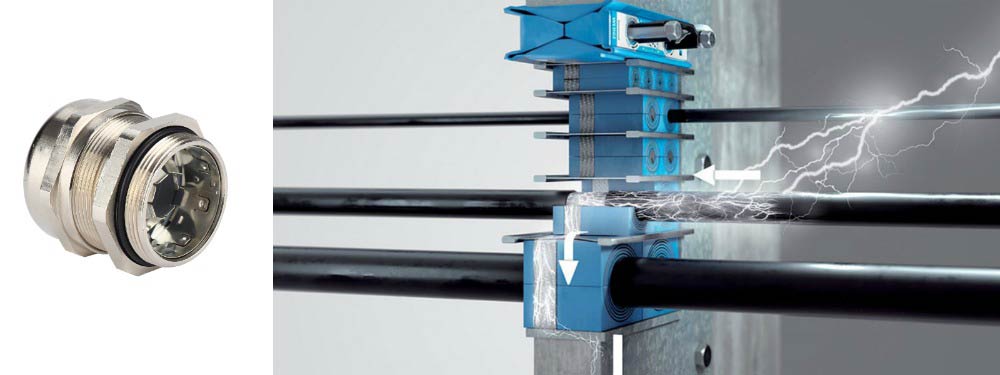

The EMC cable gland has been specially designed to use cable gland as an end body. When the isolation cable enters the EMC cable gland, the metal contact piece attached to the cable gland can be used to make contact with the metal isolation woven mesh inside the cable. In turn, the electromagnetic waves of the interference are guided to the ground line, so that the electromagnetic interference source can be evacuated. This cable gland can be fully applied to all outgoing areas where anti-magnetic waves are required.

The features of our EMC cable gland:

- Reliable connecting and wonderful sealing function

- Ideal resistant characteristic against dust, corrosion, liquid, moisture

- EMI/RFI shielding and conductive function to ensure the electrical cable working in normal condition permanently

- IP68 degree protection degree

- Working temperature from -40℃to 120℃

CEO Notes

Hey, friend! Thank you for visiting our website on EMC cable gland. Our EMC cable gland connectors are made of metal materials such as nickel-plated brass, and stainless steel. We always adopt the best material for the intermediate parts inside to ensure the shielding effect, we also have the spring type intermediate part designed for installation in some special fields. Please send me your detailed requirement now!

Questions You May Ask About Our EMC Cable Gland

EMC shielded cable gland made of metal materials such as nickel-plated brass and stainless steel, it’s depends on customers’ requirements.

Normally our EMC shielded cable gland size ranging from M12 to M80, we could make any sizes as our customer’s special design.

EMC Cable Glands Buying Guide

In recent posts, you understood that there are different types of cable glands.

And one of them is the EMC cable glands.

You see,

EMC cable glands are utilized in various applications that need shielded cables for electromagnetic protection.

Such glands help in keeping the electromagnetic integrity of the protected cable.

It is done by compressing the gland.

It also offers an IP68 protection level and strain relief to the cable.

Cable glands are normally devices which help to safeguard the end of an electrical cable.

Keep in mind that it connects to any equipment.

You will find some other names synonyms for cable glands are:

- fitting

- cable connector

- strain relief

- cord strip

These might be used on each type of:

- data & telecommunication cables

- instrumentation

- control

- electrical power

On the other hand:

The EMC cable glands are employed in the case where we safeguard cables for electromagnetic protection.

Such glands ensure that the integrity of the electromagnetic cables with ease.

Those range from most product varieties too.

Do you wish to know more about this type of cable gland?

Luckily, you are in the right place!

In this post, allow us to enlighten you about EMC cable gland, it’s function and so much more.

Are you getting ready?

Without further ado, let’s begin!

Chapter 1: EMC Cable Gland Definition: What is EMC Cable Gland?

In case you didn’t know yet, EMC refers to Electromagnetic Compatibility.

One of the essential quality attributes of electronic and electrical products is their EMC.

To guarantee hassle-free and trouble-free operation of plant, systems and electrical appliances, the fundamental EMC requirements should be met.

What’s more, electrical devices should be safeguarded from interference.

It must not interrupt along with equipment and appliances.

EMC Cable Gland Definition

Electromagnetic compatibility is the ability of an:

- industrial plant or

- apparatus

to work satisfactorily in the electromagnetic setting without causing the electromagnetic disturbance.

EMC stands for Electromagnetic Compatibility.

Therefore, the level of the influence of radiators or feathers designated of installation equipment or another electronic plan goes out.

EMC cable gland with entry cable

Electromagnetic Compatibility Metal Cable Connector or metal electromagnetic compatibility gland head can be made of high-quality brass material.

It can reduce electromagnetic interference when the cable is insulated.

This cable gland is fully resistant to 1000 hours.

UV weathering test and waterproof and tensile strength functions.

The product has anti-corrosion properties such as:

- acid and alkali resistance

- chemical resistance and;

- general solvent

It can be widely used in various fields such as:

- machine

- automatic control

- electrical

- network

- connector

- telecommunications or communication and;

- lighting

The degree of protection: within the specified bayonet range, and tighten the head with a sealing ring to achieve IP68-10Bar

Features of EMC Cable Glands

If you plan to use EMC cable glands to your project, here are the features you can get from it:

- working temperature from -40 degrees Celsius to 120 degrees Celsius

- IP68 degree protection level

- RFI/EMI shielding and conductive function to guarantee the electrical cable working in standard condition

- Prefer resistant features against moisture, liquid, corrosion, and dust

- Dependable connecting and offers excellent sealing function

Advantages of EMC Cable Gland

One of the incredible things about EMC cable glands is that it comes to various advances into one single product.

Following are some of the superior advantages of this cable gland that you should not miss.

- The components are already pre-assembled

- Suitable shielding will be accomplished only by tightening the dome nut

- To get a low electrical impedance among the cable gland as well as the braiding of the cable, the CMD cable gland doesn’t have to be disassembled

- The protection class is IP68

- You receive the similar clamping ranges as the average brass glands

Applications of EMC Cable Glands

EMC cable glands are widely used in the fields of the following:

- surveillance cameras

- lighting display devices

- solar PV modules

- power supply switches, distribution box, and motors

- wireless networking ODUs

- telecommunications

- electronic and electrical technologies

When it comes to the automotive industry:

EMC cable glands are mainly utilized in electric and hybrid vehicles.

Nonetheless, they are also utilized in traditional vehicles to safeguard the sensor.

It’s also utilized to protect on-board electronics systems from electromagnetic interference.

EMC Cable Gland Material

Did you know that EMC cable gland is typically designed and made of brass or stainless materials?

It offers suitable:

- strain relief function

- simple for installation

- short and long entry accessible for customization

The thread type could be:

- NPT type

- Metric type and;

- PG type

Based on the needs of the customers

EMC Cable Gland Function

In case you didn’t know yet, EMC cable gland has been designed to utilize the cable gland as an end body.

Once the isolation cable enters the EMC cable gland, the metal contact item connected to the cable gland can be utilized to make contact along with the metal isolation woven mesh within the cable.

For that reason, the electromagnetic waves of the interference are assisted to the ground line.

Therefore, the electromagnetic interference source could be emptied.

This type of cable gland could be applied fully to each outgoing regions where anti-magnetic waves are needed.

EMC Cable Glands Utilized in Protecting Systems to Safeguard Against Interference

Did you know what the latest telecommunication systems, high-end solutions in medical engineering, and industrial facilities have in common?

All of those systems have delicate electronic controllers.

The high-frequency electromagnetic radiations which they generate as well as the possible interference risk which they pose establish technical concerns for engineers.

Items like EMC cable glands provide a suitable shielding solution.

Such aid the engineers make sure the optimum protection is presented from electromagnetic interference.

Uninterrupted Performance in Industry and Home

When we talk about an electrically conductive cylinder, cans or box, they are perfect for industry and home applications.

Such systems cover:

- connectors

- enclosures

- cable bushings

- cables

If you employ a cable with bad shielding attenuation, even a high-class cable gland will be useless.

You are obliged to harmonize each of these components.

Through harmonizing, certified cable bushings will guarantee to shield from electromagnetic conflicts along with:

- maximum sealing and;

- maximum attenuation

When choosing the proper cable gland, you should consider some factors.

First:

Ask yourself what material you will require?

Does the region have a hazardous are rating?

Do such cable glands need to be certified in ATEX, CSA or certified in both?

What type of thread do you require on the male end of the gland?

What’s more:

The seal on your cable gland should be taken into account whenever picking the right gland.

Your gland should be sealed to the inner cable bedding.

You will find several methods to apply this.

They are as follows:

- compound barrier seal

- compensating displacement seal

- diaphragm seal

- displacement seal

- compression seal

The variations in such seals concern the nature of the application of your seal ring on the cable.

The obvious benefits of EMC cable glands include:

- environmental protection from moisture and dust, coming from the enclosure

- offering a holding force to limit pullout resistance

- in hazardous regions keep a level of protection over the equipment which it is attached to

- they are also explosion-proof, firestop, RFI, or EMI shielding

You need to take note that EMC cable glands serve its purpose well.

They are extremely helpful when connecting cables into vital components.

They add an extra element of stability and security.

Chapter 2: EMC Cable Gland Parts

In spite of its simple and small design, EMC cable glands are a vital component of electrical installations.

You see:

They are utilized in almost all areas of trade and industry.

They enable water-protected, strain-relieve cables to link to systems like:

- switchboards

- distribution boards and;

- junction boxes

EMC cable glands safeguard electrical components against environmental and mechanical forces like:

- moisture and dust

by attaching the cables safely to casings

Generally, cable glands are composed of three major parts:

- fitting

- sealing insert and

- the cap nut

The so-called EMC inserts might also be employed for cable glands for electromagnetic compatibility.

That removes the necessity for special EMC cable glands.

You will find some cable gland designs that are utilized in hazardous environments.

There were also special hygienic design cable glands that are utilized wherever sanitary cases are needed.

In this chapter, allow us to determine the various parts of EMC cable glands as well as their functions:

Sealing Nut

The sealing nut, on the other hand, offers an exceptional grip and a spanner-tight seal.

Yes, that’s right!

The multiple thread design assurances fast and protected assembly.

What’s more:

You can rest assured that sealing nuts are a very economical solution for dependable seals against liquid and gaseous media under high pressure.

Sealing nuts can be done in the bearing face or the thread.

Such components are utilized for:

- fuel systems

- pneumatic systems

- hydraulic systems

Along with a sealing nut, those high-strength screwed connections could be realized without any loss of preload forces.

They could even be utilized in repeated screwing.

A sealing nut should have unsurpassable sealing and fastening power.

It is engineered to feature 360 degrees of sealed rubber element.

That offers deterrence from:

- contaminants

- vibration and;

- external pressure

using the O ring technology.

Claw

A claw’s cable gland is produced to stay on the gland body.

It serves its purpose by saving installation expenses.

You see:

This EMC cable gland part name features a rubber ring inside the claw to grip the cable firmly.

That makes it suitable for the installation and protection of cable going inside the chassis.

Seal

In the meantime, a cable gland seal is composed of a ring.

Typically, it is made out of rubber.

It is sited inside the body of the cable gland to serve as a seal.

Remember:

The cable gland seal offers safe coverage for the cable or the entry point of the cable.

The good thing about EMC cable gland seal is that it is designed to be situated inside the sealing ring of the EMC cable gland.

After it is fitted, it will sustain environmental ingress once a cable is absent.

Thus, it can safeguard a panel or device from liquid or dust.

Some of its benefits and features include:

- A seal of IP68 rating could be reached once assembled properly

- It stops humidity from entering the gland

- It safeguards unused connection points

Body

The body of the EMC cable gland, as well as housing, are normally made out of brass.

In case you didn’t know yet:

The housing, as well as the body, include all the other parts of the EMC cable gland.

Washer

Take note that an EMC cable gland washer is also a tinny, shaped like a disk or plastic piece of hardware.

One of the features you will notice is that it has a hole in the interior.

This cable gland washer works by serving to allocate the load of a threaded fastener like the nut on the cable.

Additionally:

It is also utilized for spacing.

It depresses vibration as well.

Ultimately, it avoids corrosion and wears.

Intermediate Contact

Did you know that intermediate contact is the most important component of the EMC cable gland?

It works by contacting the screen of a protected cable to offer 360 degrees earthing.

Lock Nut

EMC cable gland lock nut is a very small, hexagonal tool.

One of its uses is that they are utilized for protecting into position almost every form of cable glands and cable grommets.

Such devices are made to link and protected the end of an electrical cable into other equipment.

You see, this cable gland parts name is utilized in a plethora of industries and sectors.

Such industries are the ones that utilize wiring and cable employed in automation systems as well as electrical instrumentations.

EMC cable gland locknuts might also be utilized on all kinds of:

- data & telecommunications cables

- instrumentation

- control and;

- electrical power

Another thing:

EMC cable glands are composed of three parts.

A spit sealing grommet and two gland halves

These parts are screwed altogether along with the brass hexagonal cable gland locknut.

To conclude EMC cable gland locknuts are suggested in safeguarding accessories and cable glands to a gland plate or equipment.

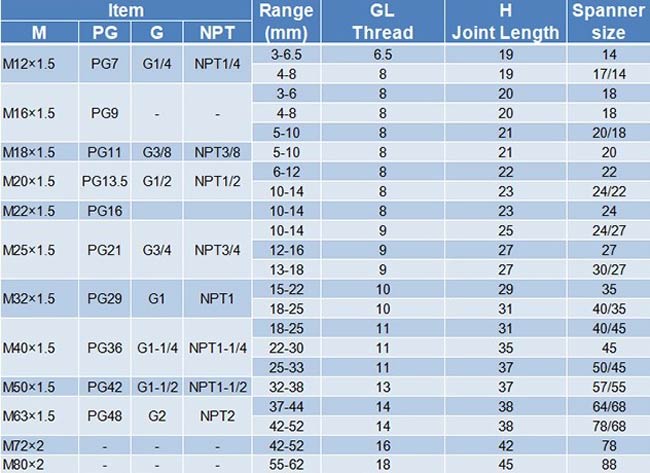

Chapter 3: EMC Cable Gland Sizes

EMC cable glands are nothing incredibly fancy.

However, picking the appropriate size and style could contribute massively to the entire proper maintenance of cables distributed.

Cable Gland Size Table

When we talk about the EMC cable gland, the approach “one-size-fits-all” won’t be operative.

You need to bear in mind that different equipment and industries have their own set of requirements and the following parameters.

Do you want to make sure the safety of your equipment and to comply with the right standards?

If so, you need to utilize the appropriate EMC cable gland size according to its application setting.

EMC Cable Gland Size Table

The table below is a guide to the proper EMC cable gland for a specific cable.

However, an individual application might need different glands.

So make sure you confirm along with the cable supplier.

Chapter 4: EMC Cable Gland Installation

Another good thing about m25 EMC cable gland is that it’s much convenient, dependable, and waterproof cable gland metal shielding.

You can easily install the small copper wire without any trouble.

- Extensive – sheathed cables could be utilized for shielding

- Dependable greater shielding surface – a much better contact

- Convenient – simple cut jacket layer as well as a shielding layer, which saves a lot of installation period

- Shielded cable – sheathed cable and other types of shielding cable shielding

Now, do you want to know the process of installation of an EMC cable gland?

Make sure you follow these steps below:

Standard connectivity

- The first thing you need to do is to strip the cable sheath and shield

- Then outside the circle along the route of the retaining layer cut at least 15 millimeters

- Out of the cable waterproof cable gland

- Get rid of the outer sheath

- Pull the cable so the contact along with the cable shield red contact

With small metal wire without a layer in the nursing

- Stripped the cable sheath and shield

- So that much outside the nursing shield layer is grown at least fifteen to twenty millimeters

- Cable out of the cable gland so the contact along with the cable shield reed contact

When the cable shielding wire connector requires to be connected with others

- Exposed shielding layer of at least 10 millimeters

- Cable out of the cable gland, so the contact along with the cable shield reed contact

Here’s another process on how you can install an EMC cable gland.

To install an EMC cable gland, make sure you eliminate 5 to 10 millimeters of the insulation of the cable.

Place the cable inside the cable gland and change it without the contact elements which touch the braiding.

Make sure you squeeze the cap, and the conductivity will be developed.

The design of your contact elements will adapt to various cable diameters based to the clamping range of the cable glands.

What’s more:

The clamping insert of the cable gland is as extended as the gland itself.

Therefore, any electrical shortcuts between the individual wires and the body will be prevented.

Also:

Narrowing the dome nut will have three various impacts:

- The cable will be positioned in the center of the cable gland.

- The design of the dome cap will offer necessary strain itself

- The chloroprene seal will guarantee IP68 protection.

All of those is achieved by simply one turn of the dome cup.

You see:

Even the process of uninstalling is much simpler. There’s one thing you need to do.

You need to open the dome cap and jerk the cable out of the cable gland together along with the insert.

That can be removed then hassle-free.

Conclusion

In the industrial field, EMC plays a very vital role, as the complicated systems and machines are prone to electromagnetic inference.

These undesired EMC impacts could be countered with the efficient shielding of each component.

On the other hand, better shielding lowers the amount of intervention produced by an electrical apparatus.

It also lowers its susceptibility to lessened performance because of electromagnetic impacts.

Not just the cable themselves but all other parts which are part of the installation should offer shielding attributes.

A passive component, a cable gland should guarantee that the quality of the shielding at delicate interconnection points keep intact.

Plus, there must be no losses because of the shielding.

For that reason, it is very critical not just to employ a maximally shielded cable.

It is also vital to add an EMC-compliant cable gland.

Even though there is no individual EMC standard for such components, they play a huge contribution towards making it possible to meet the EMC attributes given by the manufacturers.

There you have it!

Above are some of the information you need to EMC cable glands.

Just keep in mind that EMC cable glands are mechanical cable entry devices.

They can be made from non-metallic or metallic materials.

Do you want to know more about EMC glands?

Feel free to get in touch with us.

Our team will be glad to help you with your concerns about this subject.

So what are you waiting on?

With this information, you are now ready to purchase your own EMC cable glands with confidence.

What are your thoughts about this post?

Share your thoughts by leaving your comments below!