Are you planning to install cables in your next industrial project?

Well, when it comes to this thing, particularly for industrial uses, it is vital to be ready enough.

Why?

Because you want to prevent the misfortunes or disasters and the associated frustration throughout the process.

That also includes the selection of the appropriate type of cable glands for your industrial project at hand.

You see:

The last thing which you wish is to have the wrong an inappropriate cable fitting at hand.

That’s especially true when the task is about to reach its completion.

Or to see that your cable fittings which were ordered are of the wrong types of cable glands or cable gland size.

In this e-book, allow us to present you the information you need about:

- cable gland size calculation pdf

- the type of cable glands;

- how to choose the right cable gland sizes for your needs

Are you now ready?

Let’s get started!

Chapter 1: Different Types of Cable Glands and Size

Cable glands are tools which you can connect to the end of the cable, to safeguard it to the equipment.

It also keeps the wires clean, and not all around the place.

Such handy tools could be utilized for:

- electrical power

- data cables

- instrumentation

- control

- telecommunications

Fundamentally, the majority of industries will be employing them frequently.

Did you know that different types of cable glands also need different cable gland size calculation excel?

Yes, you read that right.

In this chapter, we will present to you the different types of cable glands and their cable gland size table.

Let’s dive in!

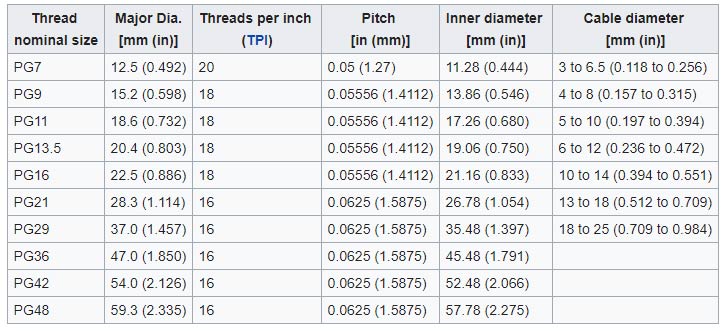

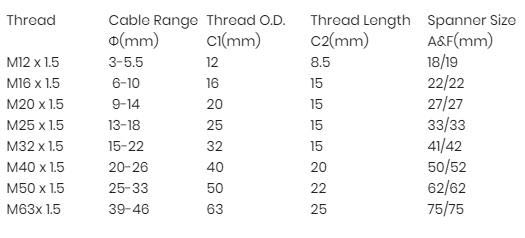

PG Cable Gland Size

FAST FACT!

Did you know that PG is the acronym for panzergewinde?

Their sizes are named with the prefix PG plus a nominal number.

These numbers are corresponding at least to the maximum cable diameter which can be passed thru the conduit.

These days, PG cable glands are still seen on:

- bioreactors and;

- chemical reactors

The PG series cable glands start from PG7 to PG63 as normal sizes in the worldwide market.

For instance, PG16 thread for screwing in sensors and several other types of equipment, connectors, and junction boxes.

Below, we listed the essential information about the thread nominal size of PG cable glands.

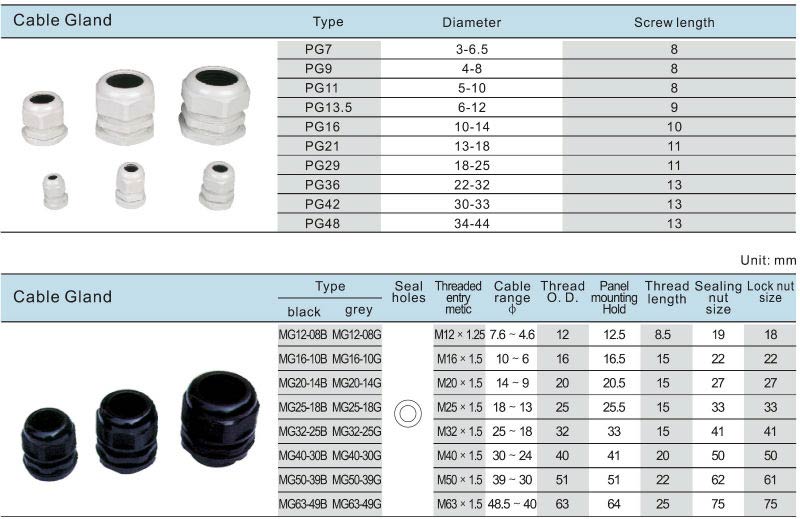

Metal Cable Glands

Metal cable glands are utilized in a wide array of applications.

Stainless steel cable glands and brass cable glands is the most popular types of metal cable glands in the various applications, both of them have advantages of and disadvantages, you could check their difference before your purchasing decision.

Stainless steel cable gland size chart

These applications include:

- technology

- the chemical industry;

- areas with high demands on chemical and mechanical stability

The benefits of using metal cable glands are its durability over time.

That’s true even in the wet settings, as well as its rigid stability.

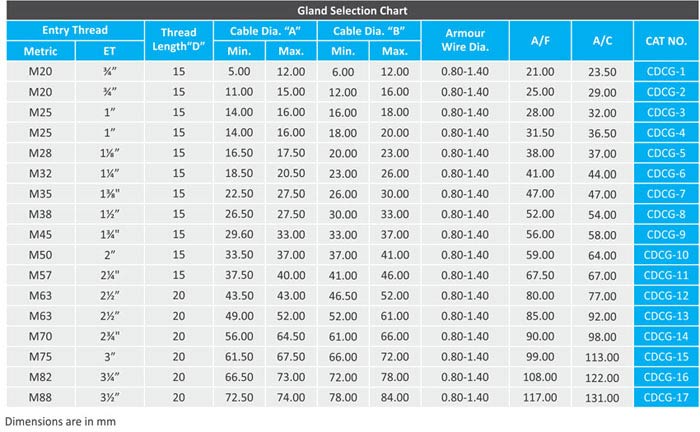

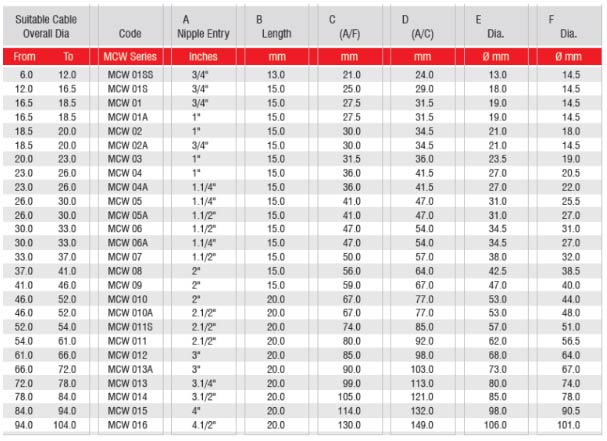

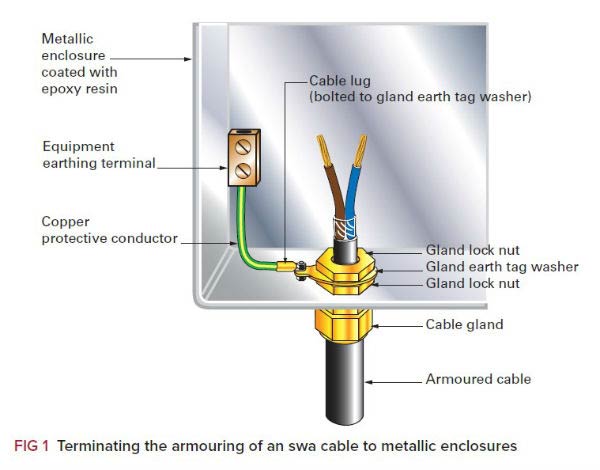

Armoured Cable Gland Sizes

On the other hand, armoured cable glands feature an added layer of protection to keep it from being abraded or cut.

The armor layer of the coax cable is a foil wrap which is ribbed as corrugated metal.

That will enable for flexibility, around the outside and inside of that wrap.

The armoring materials commonly come from:

- aluminum foils

- steel

- Kevlar

They aim to safeguard the armoured cable from being stretched throughout the installation.

Armoured Cable Gland Size Chart

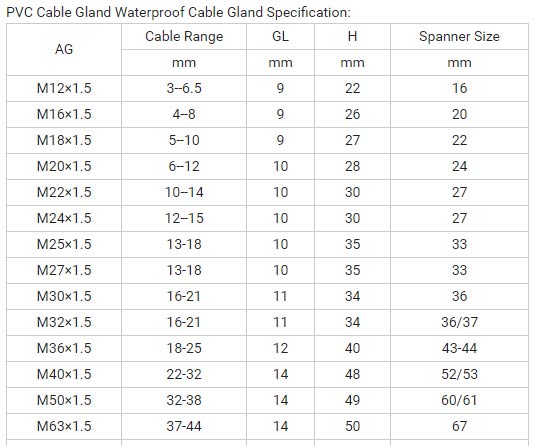

PVC Cable Glands

Meanwhile, PVC cable glands are widely used for:

- Machine

- Electrical

- Distribution plate

- Machinery control box and many others

PVC cable glands size chart

Nylon Cable Glands

Apart from the major types of cable glands, like armoured, PVC, metal, and PG, there is also nylon.

Instead of using the early mentioned type of cable gland, why use nylon?

You see;

Nylon cable glands could come in various colors.

Some are blue and red that denotes you could color code the cables.

If utilized in particular facilities, a color-coded system of 300 cable gland size, for your telecommunications or data application, would surely make maintenance much easier and efficient.

A nylon cable gland might also bear the highest IP rating.

It has at least IP68.

What’s more, it might have a flammability ratio of UL94 V0.

That’s a standard for the safety of flammability, in the occurrence of burning.

It will stop in just ten seconds on some vertical specimens.

Below is the

Nylon cable gland size chart

What’s more:

The nylon cable gland is primarily created to have a resistance to ultra-violent in outdoor applications.

The advantages of this type of cable glands are a high rate of strain relief.

Plus, it also has an expansive operating temperature that ranges from -40 degrees Celsius to 100 degrees Celsius.

Plastic Cable Glands

Plastic cable glands have a wide array of cable ranges.

That’s because of their seal and claw design.

That makes it entirely flexible to a wide array of applications.

The best thing about this type of cable glands is its resistance to:

- weak acids

- greases

- saltwater and many others

Check out cable gland size table of plastic cable glands.

Plastic cable gland size chart

Double Compression Cable Gland

Such outdoor and indoor cable glands are for use with all kinds of unarmoured and armoured cables.

It offers environmental seal for the outer and inner sheath of the cables.

These type of cable glands also offers electrical continuity and cable retention.

That can be achieved through armor wire termination.

Apart from that:

A detachable armor and anyway universal clamping ring scheme enables the cable to be disconnected easily from the equipment.

That is for change, maintenance, and many others.

You see:

Double compression glands also offer added support to the bulkier armoured cables that exit or enters the panel.

Some of the components of a double compression cable gland are composed of:

- clamping ring

- outer seal

- support ring

- inner seal

- cover nut

- lock nut

- armor cone

- gland body

- compression nut

- flat washer (PVC)

Double compression glands are dust-proof and weatherproof.

They can be utilized in normal climatic settings.

Also when shielded by PVC shrouds, it can be utilized in corrosive settings.

Below is the double compression cable gland size chart:

Double compression cable gland

There you have it.

These cable gland size table will surely help you know the different sizes of different types of cable glands.

In the next chapter, we will present you essential information on how to perform cable gland size calculation excel the proper and simple way.

Chapter 2:How to Calculate the Cable Glands Size in Correct Way?

In this chapter, we will educate you on the proper way to calculate the sizes of your cable gland.

When we talk about installing cables, particularly for industrial uses, it is vital for you to prepare enough.

That’s true especially if you want to stay away from the casualties as well as the frustration connected to it.

That might be composed of:

Choosing the right kind of cable glands for the project you have

What’s more, the last thing you wanted is to have the mistaken cable fitting at hand once your project is about to reach its final accomplishment.

Much worse, to see that your cable fittings which were ordered are the wrong kind or type.

In this chapter, we hope you learn something relevant about cable gland size calculation pdf.

Are you now ready?

Let’s jump in!

Cable gland size calculation

The ideal time to choose the size of your cable fittings to be utilized must be throughout the planning level.

Why is that?

That’s because that will get rid of the stress and hassle of identifying the 300 cable gland size once the project is about to be completed.

That, in turn, could leave more room for miscalculations.

When we talk about choosing the size for your cable fittings, bear in mind that there are two major and crucial things you need to take into consideration.

The first thing is:

You or your cable installer or contractor must identify the type of cable that is to be employed for the project at hand.

Then, it is valuable to consider the cables:

- construction

- size

- materials utilized

when manufacturing it

Now:

Is your project at hand needs the use of some armoured cable?

Then, you will find some factors which should be taken into consideration and determined before you buy your cable fittings.

Armoured cable gland installation

- The first thing you need to do is to check the type of armor cable.

- Make sure that you also check the materials utilized in producing it.

- Then, you need to check the short circuit fault current rating of the cable.

- Do not forget the inner bedding, lead covering, and even the entire cable itself.

- Next, make sure that you identify whether you will require a cable gland with protective plating or corrosion protection.

Doing this will be applicable for use in regions with particular environments.

You must also check the materials utilized within the mating electrical enclosures.

Remember that when you use incompatible metals, it can result in massive side effects.

- Afterward, make sure that you also check the entry hole of the cable.

That includes the size and its type in connection to the electrical equipment where it will be connected.

Other vital things you need to consider is to check the:

- entry head seal

- shrouds

- earth tags

- whether accessories such as washers and lock nuts are to be employed

- whether reducers or stopper plugs or reducers are needed

Bear in mind that doing your research ahead of time of the actual installation of the cable gland is essential.

That’s because it will enable you to prevent the trouble of selecting the wrong cable gland size table.

For example: PG7 cable gland with the cable clamping range 3-6.5mm, that means the electrical cable diameter size must be in this range, otherwise, you should change another size to match it.

What’s more, it will also facilitate the fast accomplishment of your installation.

Apart from that, ensure that after the installation process is completed in high-risk regions, local and international safety standards, the prevailing industry is followed.

That is to prevent any unfortunate incident.

In the next chapter, we will educate you about some tips on how to choose the right cable gland size for your project needs.

Chapter 3:How to Select the Right Cable Glands?

In this last chapter, it is time for you to understand the tips and tricks on choosing the right cable gland.

You are already aware that a cable gland does a number of vital roles in cable management.

It is created to connect and secure the end of an electric cable as well as the device it is attached.

Cable gland offers:

- bonding

- insulation

- grounding

- earthing;

- strain relief

They could also be utilized to close cables that pass through the bulkheads of the gland plates.

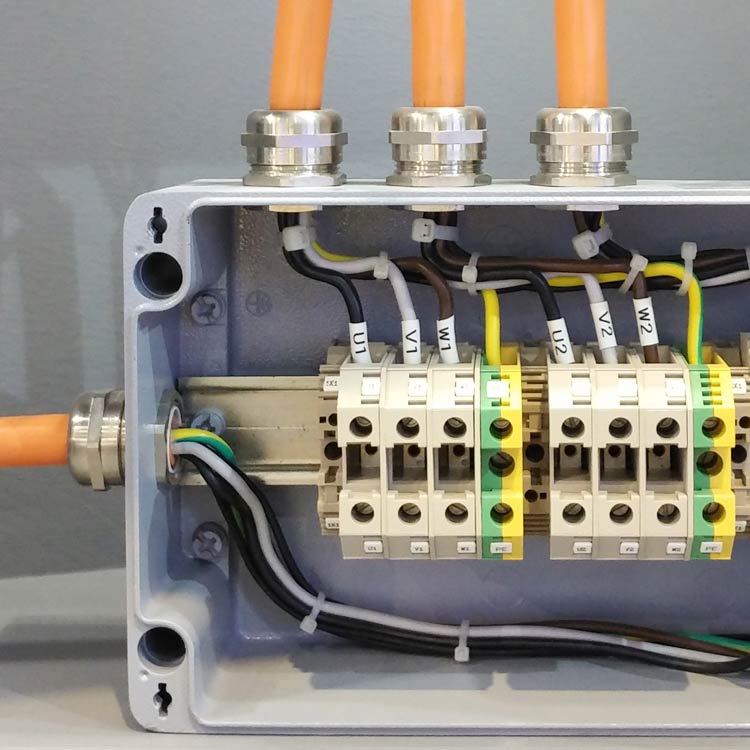

Cable glands in electrical enclosures

You see:

They are often situated in harsh or hazardous settings.

It’s the environments where they should include electrical sparks of flames.

They could also repel outside contaminants like:

- fluids

- dirt;

- dust

Apart from this, their role is to prevent cables from becoming pulled or warped.

That is to guarantee a continual performance and secure connection.

Now, how do you determine which cable gland is ideal for your application?

The Variety of Cable Gland

Did you know that different industries have its particular requirements?

Of course, you’re aware of that.

That is vital to pick the right cable gland to fit your application environment.

Cable glands in machine

What’s more:

There is a realm of options, and unluckily, no one size fits all option.

However, it does denote that you can personalize a cable gland according to your parameters.

But, how can you do that?

You first need to take into consideration a wide array of application and environmental factors.

What is the Role of the Environment?

Remember that it does not matter if you are working in:

- telecommunications

- power & utility

- marine

- industrial

- aerospace or

- any other key industry

What is vital in determining the core application setting of your cable gland?

Are you planning to use your cable gland outdoors or indoors?

Will it be located in a hazardous, industrial or explosive setting?

What is the current temperature and is it stable?

Is the surrounding place dusty or damp?

Are these any corrosive or gases materials close?

All your questions will help identify the specs of cable gland.

It will also determine whether it needs a special protective coating or plating,

Understanding the Type of Cable

Various cable glands need various types of cable glands.

Simply put:

The requirements for an unarmored cable are different from those of armored cables.

You see:

Unarmored cables could be more basic and don’t have a seal, double or single outer seal.

On the other hand, armored cables have added a layer of protection to avoid damage.

That might be:

- double steel tape armor

- pliable wire armor

- braided armor

- single wire armor

For both kinds, you also need to take into consideration:

- cable material

- construction size

- cable diameter

For armored cables, you need to consider the following:

- the size and type of the armor braid

- the short circuit fault rating of the cable armor

- the diameter of the head covering

- the diameter of the inner bedding

Select a Material Type

Different materials of cable gland do differently that depends on the:

- cable type

- environment and;

- application

The three major types of metal are:

- stainless steel

- aluminum and;

- brass

You will also find a wide array of nylon and plastic cable glands to choose from as mentioned in the earlier chapter.

Types of Mounting

Depending on the application requirements, you will find a full option of cable gland mounting.

They include:

- cast

- welded

- mount

- nut or threaded

- bolted or flanged

- compound or adhesive

Added Protection Features

Your environment or application may need the cable gland to obtain a particular quality.

That is where you might take into consideration one of the following features:

- liquid tight cable glands to safeguard against penetrating waters and oils

- wire mesh for added strain relief

- Romex connections to deal Romex cables specifically

- RFI and EMI shielding and linked grounding features to lessen or remove electromagnetic or radio frequency interference

- Explosion-proof cable glands

- Fire-stop cable gland that can endure fire propagation thru a barrier

Standards and Ratings

Cable glands are always created along with safety in mind.

You see:

They come with a rating system to guarantee you understand what you are getting,

Apart from that:

The IP rates, also known as Ingress Protection Marking rates the glands depending on the efficiency and design throughout various tasks.

Such rating sometimes goes up to IP69K and IP68.

Any cable glands you purchase these days will be covered as well by the new European standard for cable glands, EN50262.

Therefore:

It is very crucial that you check any devices positioned in explosive settings comply with local or global codes of practice.

Below is a final selection checklist you need to know when choosing cable gland.

You will find some vital considerations which fall outside of the classifications above.

So, before you select a cable gland, you need to ask yourself the following questions first:

- Is there a requirement for stopper plugs to seal off any unused cable entries?

- Is the cable gland depth and size for 185 sq mm cable gland thread metric or PG?

- Is the mounting hold diameter big enough for your cable gland?

- Is the pressure rating high enough for the needs of your application?

- Is the cable diameter enough?

- Is the wire hole diameter big enough to cover all the cables within the system?

Conclusion

There you have it!

We hope we give you something relevant about cable gland sizes and the types of cable glands.

Just bear in mind that cable glands offer super environmental protection in various types of applications no matter what cable gland size calculation you perform.

If you are looking for the best cable gland with different sizes, we got you covered!

We have the best cable glands from:

- PG cable glands

- Metal cable glands

- Nylon cable glands

- Plastic cable glands

- Double compression cable glands

- And so much more

No matter what size you’re seeking for, rest assured that we have them all.

What are your thoughts about this post?

Share your thoughts with us by sharing your comments!

We’d love to hear them all!