Electrical Cable Gland

As one of the leading cable gland manufacturers in China, our electrical cable glands are made in a wide range of sizes in mm from 6mm to 100mm. We have different material types of electrical cable glands such as stainless steel cable glands, brass cable glands, and nylon cable glands.

Electrical cable gland designed for flexible conduit wire in electric equipment providing sealing and strain relief function. It could be applied to different types of electrical cables such as armored and unarmored cables, some of them especially installed for electrical enclosures with cable entry.

Electrical cable glands wide used in different applications and are called single-compression cable glands, double compression cable glands, high-pressure cable glands, shielded cable glands, armored cable glands, explosion proof cable glands.

CEO Notes

Hello, thanks for visiting our website on electrical cable gland. Our electrical cable glands were installed for different applications with different functions as you need, some types applied for armoured electrical cables, and some types with IP68 waterproof functions, and explosion-proof function, etc. We could provide different types& sizes of electrical cable glands according to your customized design drawings, please contact me when you need any help. Thanks!

Questions You May Ask About Our Electrical Cable Glands

The electrical cable glands are normally installed in the electrical boxes& enclosures for wires entry.

The HS code for the electrical cable gland is 8547901000

Firstly, you should know the electrical cable types, for example, Armoured electrical cables or unarmoured electrical cables.

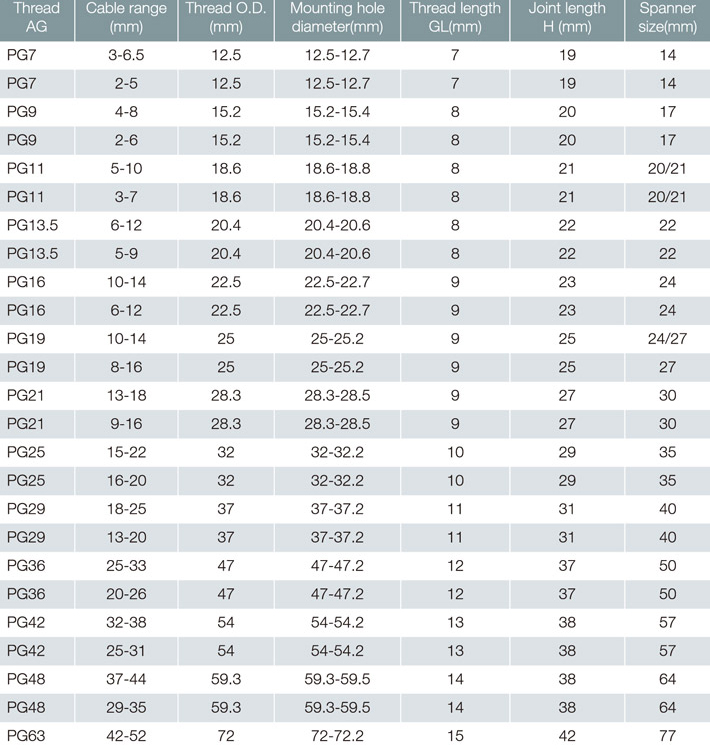

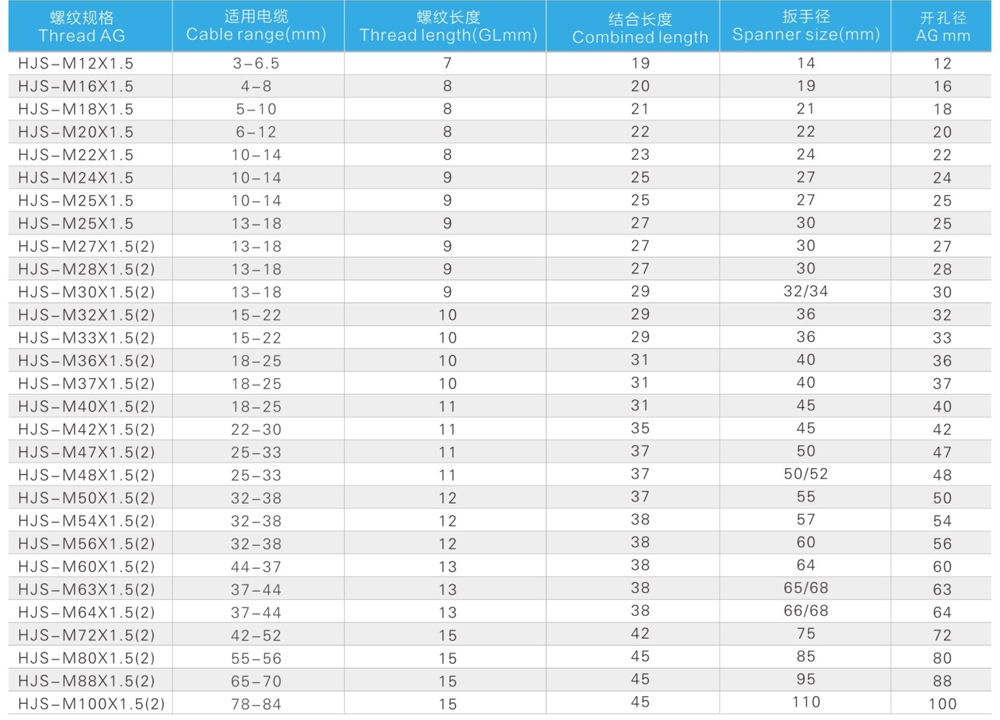

Then you should confirm the thread types of the electrical cable glands, there are PG, NPT, Metric threads, etc.

Finally, you should tell us the outer diameter of the electrical cables, the electrical cable glands have clamping ranges for different sizes of cables, and we will tell you the suitable glands sizes.

Electrical Cable Gland: Ultimate Buying Guide

Introduction

Introduction

Is the product exposed to the elements and problems growing, which dirt and water could pollute the delicate electronics?

Have you ever considered employing electrical wire gland to seal off your cables and wires, which pass through the electrical enclosure?

They are the perfect solution if optimum protection is needed.

In this post, allow us to provide you all the information you need about electrical cable gland.

Throughout this short guide, we will equip you with information about:

- what is electrical cable gland

- applications of gland for electrical cable

- electrical cable gland sizes

- types of electrical cable glands

- different parts of a cable gland and;

- installation of electrical fitting

Without further ado, let’s begin:

Chapter1: Electrical Cable Gland Definition: What is Electrical Cable Gland?

Have you heard of electrical cable glands?

In case you didn’t know yet, an electrical cable gland is a type of cable entry system, which connects to and secures a cable to electrical equipment.

Electrical fitting enables the wire or cable to enter an enclosure while it seals out:

- liquids

- dirt

- dust

and offering strain relief

Electrical gland connectors are utilized as a termination and sealing device.

This device is utilized to make sure that the attributes of the enclosure that the wire or cable enters could be sustained sufficiently.

Electrical cable glands are utilized in conjunction with wiring and cable throughout:

- automation systems and;

- electrical instrumentation

These are utilized on all kinds of:

- telecommunications cable

- data cables

- instrumentation tables

- control cables and;

- electrical power cables

The wide selection accessible meets the International Protection Rating.

It is a standard to offer the highest level of protection based on its international standard.

As a plus, an electrical fitting offers practical strain relief.

The ever-growing line of such items is simple to use.

They are also supplied in different sizes and in three threads:

- metric

- G

- PG and

- NPT

along with the other parts having washers and optional lock nuts accessible

When the enclosure is sufficiently thick, you can easily thread them into a threaded hole.

For a small sheet metal enclosure, you can use gasket or lock nut to seal.

An electrical cable gland is the perfect power source for the connection cable.

It also safeguards the cable, so it doesn’t escape.

Gland for electrical cable is positioned in various categories depending on whether the glands are utilized in the processing sector or where protection is needed to avoid explosion hazards or too much temperature.

A variety of cable gowns, which fit into the gland and various types of the gland, will be needed.

The gland itself could be made of metal such as:

- nylon

- stainless steel

- brass

The materials are practical in various environment.

Electrical Cable Glands Applications

As mentioned earlier, electrical cable glands are utilized in different cables; from data to telecommunications.

But did you know that electrical fittings could be utilized to offer maximum protection to machinery as well?

Effectively machinery protection is vital for smooth and continued production.

With the extreme cost of pieces of equipment, you cannot ignore the significance of protection against:

- water

- dirt

- dust and;

- other foreign debris

For that reason, electrical junction box glands offer a cheap solution to offering the security, which is vital for electrical equipment and types of machinery.

Such parts can safeguard internal electronics from water and dust.

It also adds an aesthetic finish for machine protection and cable protection.

The major applications of an electrical cable gland are to serve as a terminating and sealing device.

It guarantees the protection of enclosures and electrical equipment, including the provision of the following:

- added environmental sealing

At the cable entry point, keeping the ingress protection rating of the enclosure along with the selection of applicable accessories committed to doing this function

- added sealing

On the region of the cable reaching the enclosure, if a great level of ingress protection is needed

- holding force

On the cable to make sure sufficient levels of mechanical cable “pull out” resistance

- earth continuity

In the case of an armored cable, if the cable gland features a metallic construction.

The electrical cable glands might be tested to make sure they can endure a proper peak short circuit fault current

- environmental protection

Through sealing on the other cable sheath, excluding moisture and dust from the electrical enclosure

Chapter2: Electrical Cable Gland Sizes

Did you know that electrical cables have various sizes?

Typically, experts note the outer diameter to seek matching electrical cable gland.

For instance:

A 5 X 1 millimeter size electrical cable.

It’s approximate outer diameter (O.D.) is 11 millimeters.

Therefore, PG16 (10 to 14 millimeters and 7 to 12 millimeters are both appropriate for it.

On the other hand,

For metric thread type cable gland M20 (6 to 12 mm), M22 (10 to 14 mm) and M24 (10 to 14 mm) are perfect for it.

In short, you could pick the small size cable gland along with cable ranges such as 11 millimeters.

M20 is much affordable than M24 too.

Chapter3: Electrical Cable Gland Parts Name

What are the different parts of an electrical cable gland?

In this section, we will categorize each of them.

- Earthing Tag

This cable gland parts name acts as a mode of connection over the cable gland.

It ensures earth continuity among the electrical equipment and the cable gland.

It could also be coated or plated according to the specifications of the client.

- Clamping cone

Another electrical gland components you must be aware of is the clamping cone.

You see, this cable gland parts name enables clamping of the round and square pipes.

It is achieved by placing them simply.

Clamping cone is always connected together with bolts.

- O ring

An O ring is are designed of elastomers like rubber and silicone.

Nonetheless, some of them are made of plastics too.

You will find some other materials as well.

Some are created to resistant to chemicals for use in lab equipment.

O-rings are available in a broad spectrum of sizes in both O-ring kits and single size packs.

What’s more, they are also accessible if you prefer a set of seal part.

That will make sure you have the appropriate size available.

- Washers

Washers’ main function is to assist distribute a load of a threaded quickly like the nut on an electrical cable gland.

These cable gland components are used mainly for preventing wear.

It is also used to prevent corrosion, reduce vibration, and provide space to the cable gland.

- Body

The body of your electrical cable gland is commonly made of aluminum, stainless, plastic, and steel.

Most cable gland body includes other parts of the cable gland.

- Seal

This electrical gland cover prevents particle, fluid, and vapor leakage.

Its job is to protect and keep the pressure while keeping any debris out.

The seal also makes sure the proper function and safety of the cable gland.

Seals are mostly employed in various sectors like automotive, engineering and aerospace.

Seals are made of rubber, and they are located inside the cable gland body to act as a seal.

- Cable gland claw

On the other hand, a cable gland claw is designed to help maintain the gland body.

It functions by saving any installation costs.

You might notice that it has a rubber ring inside the claw, allowing a firm grip to the cable.

Cable gland claw works best for installation and protection of cable entering the chassis.

- Cable gland sealing nut

An electrical gland nut offers reliable protection and seals against:

- gas

- liquids and;

- even in under high pressure

Having a 1-piece cable gland sealing nut enables you to fit it easily with a captive seal, preventing any loss.

Are you now familiar with the different electrical gland parts name?

Next, we will discuss the different types of electrical cable gland and keep reading to know more.

Chapter4: Types of Electrical Cable Gland

Aside from the different parts of electrical cable gland, it’s functions and applications, you also need to know about the different types of electrical fitting.

In this section, let’s uncover the different types of electrical wire gland.

You see, there are various types of the e-cable gland.

In fact, they are categorized into different sections:

- by materials

- by Shape

- by thread

- by compression types

- by functions

- by waterproof degrees and even

- by applications

We will identify each of them so, read carefully.

By Waterproof Degrees

Electrical fittings are categorized in different waterproof degrees:

- IP69 electrical cable gland

- IP68 electrical cable gland

- IP67 electrical cable gland

- IP66 electrical cable gland

All these IP ratings are also known as ingress protection.

They are employed to identify the levels of sealing efficiency of the electrical cable gland from the invasion of dirt and moisture.

By Applications

You are already aware that electrical gland connectors have many uses.

General applications of electrical fittings include:

- industrial applications

- motor applications

- marine applications

- electrical applications and;

- instrumentation applications

By Compression Type

You might hear single compression cable glands and double compression glands.

You see, these two are the cable gland types according to different compressions.

These two have a difference, as well.

Single compression can be utilized in average climatic settings.

Meanwhile, double compressions are employed where huge armored cables are entering the board.

By Thread Type

Aside from electrical cable glands types according to waterproof degrees, compression, and applications, there are also types of electrical fittings based on threads.

This is composed of the following:

- metric thread electrical cable gland

- PG thread electrical cable gland

- G electrical cable gland

- NPT electrical cable gland

These four have already mentioned and discussed in the second chapter.

You can read them again if you are still confused about their functions.

By Shapes

Have you noticed the different shapes of cable glands you use?

If yes, you are aware that some are straight while some are right-angled.

That tells you that there are two types of electrical fittings based on shapes.

Straight electrical fittings are ideal for fixing the ends of flexible corrugated fittings.

Whereas the right-angle electrical cable glands also known as 90-degree electrical wire gland, offers protection when extracting the cable in a right angle route.

By Functions

We now arrive at the different types of electrical wire gland according to functions.

This is composed of:

- breathable electrical cable gland

- flexible (or spiral) electrical cable gland

- armoured electrical cable gland

- EMC electrical cable gland

- explosion-proof electrical cable gland and;

- waterproof electrical cable gland

By Materials

Finally, you must be aware that electrical fittings are also categorized in different material types.

Some of these material types are the following:

- PVC electrical gland connectors

- plastic electrical gland connectors

- aluminum electrical gland connectors

- nickel plated electrical gland connectors

- stainless steel electrical gland connectors and;

- nylon electrical gland connectors

Chapter5: Electrical Cable Gland Installation

Finally, you will now be guided on how to install an electrical fitting.

The installation procedure is very simple.

All you need to do is to follow the simple steps we will provide.

- Choose the proper cable gland size with the help of a physical dimension of the cable.

- Divide the cable gland into 2 sub-assemblies B and A through unscrewing the entry component from the body.

- Identify conductor length needed and strip back the outer cable sheath as well as the armour to fit the equipment geometry.

- Tighten the entry component.

- Pass sub-assembly B and clamping ring over the cable.

- Slide reversible armour cone in the orientation to fit the cable braid into the compensating sleeve.

- Pass the cable via sub-assembly A.

- While keeping pushing the cable forward to keep the armour in contact, secure compensating sleeve to the entry component.

- Remove the cable braid by securing entry component along with a spanner. Tighten the body into an entry component with a help a second spanner.

- Thru a standard spanner, secure the outer seal nut into the body until it arrives in an efficient stop.

There you have it! We hope in this simple and short guide, we helped you know better about electrical cable gland.

Share your insights with us by leaving your comments in the comment box below!