You will find various brass cable gland manufacturers who create cable cleats, cable accessories, cable lugs, and cable glands.

You might also be aware of the fact that there’s a wide array of cable glands accessible for different applications.

Therefore, how would you pick the best one?

What things must you take into consideration while putting your trust in a brass cable gland manufacturer?

In this post, we will delve into the details and find out.

Below are the top five most important factors for brass cable gland manufacturers.

1.The Machine Numbers for producing brass cable gland

The machine numbers determine the production capacity of a factory.

These machine numbers play a very important factor in the process.

It’s the decisive factor.

2.The Engineers controlling the brass cable gland quality

A powerful technical engineer team could ensure the design level and control the quality at the top of the production line.

Brass cable glands are utilized in explosive settings.

The safety of the electrical equipment is of utmost significance.

Thus, electrical component engineers with long years of experience who sustain high-quality standards must be dependable.

The other factors are the timely delivery of the products to the local and global market.

The engineers and the company must have a powerful logistic team who can provide sufficiently as per the

requirement. Sometimes, the engineers must design the brass cable gland according to customer’s special

requirements.

3.The Certificates for brass cable gland

You are well aware that cable glands are utilized under various environmental conditions.

Thus, the components must be tested rigorously and repeatedly.

A cable gland manufacturer should have the ability to run different quality checks.

No compromise must be made with the quality of the item and excellence at every level is necessary.

Various quality checks should be performed to make sure every component is quality tested as per local and global standards.

Some of the famous standards a brass cable gland manufacturer should comply are the following:

CE certificate for the European market

This is also referred to as product’s passport for the markets within the European Economic Area.

CE marking allows the free movement of an item within this area in the sense of the free movement of goods.

ROHS certificate for the European market

This limits the use of particular hazardous materials seen in electronic and electrical products.

ISO quality management system certificate

This is composed of processes, procedures, and policies for planning and implementation in the core business area of an organization.

IP68 waterproof certificate

It shows the waterproof function of the cable gland reach IP68, that’s an important standard for cable gland)

ATEX certificate

It shows the cable gland has good explosion-proof function.

It could be used in a hazardous area.

4.The Production Management for brass cable gland workshop

First, the pre-production technical submission is very critical.

Before each operation, it is recommended that the relevant team leader or machine monitor make safety technical submission.

This is to ensure that every producer understands the main objectives and planned output of this operation.

Secondly, we have a clearer understanding of the:

production process and product specifications,

wall thickness,

color and;

size

Technical safety before production is not only conducive to improving overall works efficiency.

But it also can control the quality of joint cable products.

Thirdly, in the production process of cable joints, relevant manufacturers must do a good job in the management of

their:

materials,

positions and;

finished products

Fourthly, managers should plan rationally according to the:

performance,

processing range,

on-site operation conditions and;

output task standards of the equipment.

Never overload production and processing operations for a long time.

This will not only make the operation of the equipment exceed the expected standards.

It will also lead to the quality of cable joints.

It can meet the standard.

Fifth, long-term production and processing will inevitably lead to certain damage or malfunction of production

equipment.

It is necessary to do the corresponding maintenance work regularly.

That’s true to make its production force better meet the production of the next cable joints,

Take effective maintenance operations.

Avoid the occurrence of failure problems to ensure that the output and quality are effectively guaranteed.

5.The fund for producing brass cable gland

Brass material needs much cash to buy.

Therefore, it is a big pressure for the fund chains.

For example, a brass cable gland factory with a turnover of 5 million US dollar.

This factory should have 3 million dollar funds in the brass raw material stock in the workshop.

Therefore, the fund amount is very important, and it could influence the production capacity deeply.

Other Factors to Consider:

Apart from the things we mentioned above, here are bonus factors you must also check:

- Latest Technologies

Take note that a brass cable gland manufacturer must always keep up along with current technologies.

They must also create new components.

An excellent and sought-after manufacturer and supplier of electrical components would expect the need for

the customer within the market.

They will leverage the current technologies and sophisticated machinery to generate advanced brass cable glands and

other electrical equipment.

- Quality of the Brass Cable Gland

A cable gland is made of brass, steel, aluminum, and different plastics.

As brass is a mix of copper and zinc, it can withstand corrosion efficiently.

It also neutralizes high temperature effortlessly.

That boosts the life and the durability of your cable gland.

Thus, brass cable glands could be utilized for outdoor and indoor applications.

This is another vital reason why you must consider a manufacturer who generates top quality brass cable glands.

- Range of Cable Glands

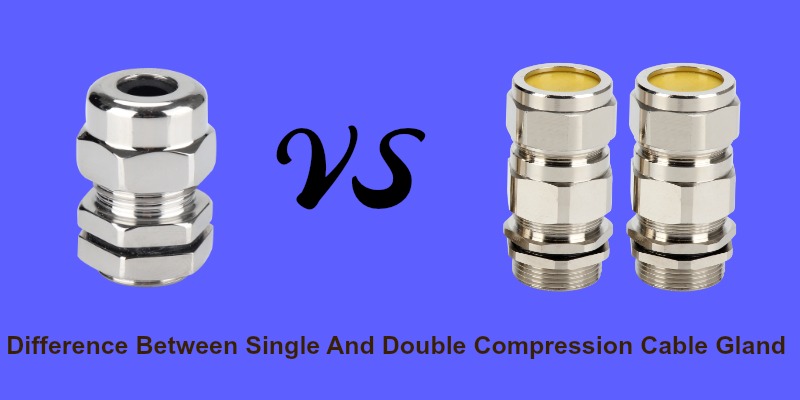

You will find two types of cable gland. One is armored, and the other one is unarmoured.

Some are utilized for industrial uses while some are intended for heavy-duty sectors.

That clearly recommends that you must seek for a brass cable gland manufacturer who offers a broad spectrum of

cable glands.

That manufacturer should be able to fulfill your cable gland requirements.

Do you think you are ready to choose the best brass cable gland manufacturer?

If so, we wish you good luck with this journey.

If you have any questions related to brass cable glands, feel free to leave your comments below.